OEM/ODM Silicone Manufacturing You Can Trust

Bring your vision to life with our full-spectrum OEM/ODM services — fast sampling, precise molds, custom logos, and packaging all in one place. We turn ideas into scalable products, with quality and flexibility at the core.

As a trusted OEM/ODM manufacturer behind leading consumer silicone brands, HaoTian Group delivers end-to-end contract manufacturing solutions.

With over 12 years of experience, we specialize in custom silicone products and professional silicone molding services, helping brands bring their ideas to life with precision, quality, and speed.

HaoTian works closely with brand owners, product development managers, and senior product designers across various industries, offering comprehensive OEM and ODM services — from silicone product design and prototyping to contract manufacturing, printing, and packaging.

Our Custom Silicone Product Service supports full customization, including material, hardness, size, design, function, structure, shape, color, logo, pattern, packaging, labeling, and more. We provide complete technical support to ensure your project’s success.

With the entire silicone product development cycle under one roof — from design and tooling to full-scale production — we help you minimize risk, reduce time to market, and lower overall costs by eliminating the need to manage multiple suppliers.

From sketch to shelf, we help bring your silicone product vision to life.

Our vertically integrated facility features expert design engineers, in-house mold making, modern silicone molding workshops, post-processing, strict QC, and customized packaging — everything under one roof for faster turnaround and consistent quality.

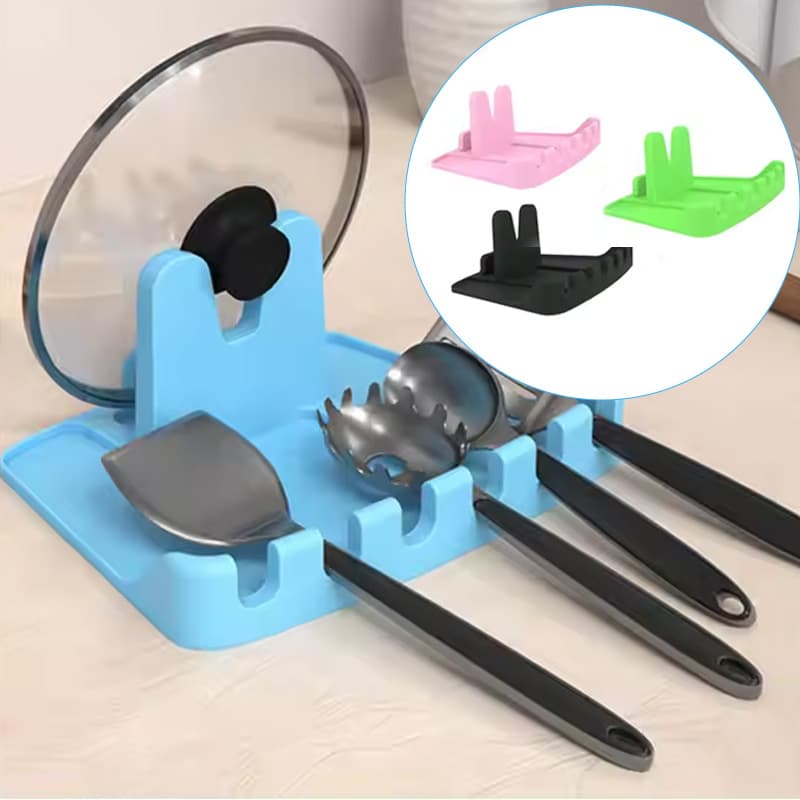

Customized silicone product

Backed by years of technical know-how, we’ve delivered more than 10,500 custom silicone product projects to our global partners.

These projects cover a diverse range of silicone solutions, including:

Custom Silicone Mats

Custom Silicone Molds

Custom Silicone Cup

Custom Silicone Bowl for brands

Custom Silicone Bag

Custom Silicone Spoon

Custom Silicone Tray

Custom Silicone Watch Bands

Custom Silicone Lids

Custom Silicone Sleeve/Boots/Cover

Custom Silicone Containers

Custom Silicone Accessories

Custom Silicone Boot

Custom Silicone Bottle

Custom Silicone Box

Custom Molded Silicone Product

Custom Silicone Case

Custom Silicone Coasters

Custom Silicone Cover

Custom Silicone Holder

Endless Customization. One Perfect Product.

We provide unlimited options in material, design, color, branding, and packaging — giving you full creative control to develop silicone products that reflect your brand and stand out in the market.

Custom Silicone Colors & Printing Services

You can fully customize your silicone product color based on the Pantone color chart. We incorporate FDA-approved color paste directly into the silicone material during the mixing process. Standard colors include white, red, green, and gray, but we also offer double-color, marble, and multi-colored molded silicone products upon request.HaoTian has an in-house printing workshop equipped to bring your designs to life. We offer a variety of logo and pattern printing options, including silk screen printing, pad printing, heat transfer printing, water transfer printing, in-mold decoration, and digital printing — all designed to match your branding needs perfectly.

Our in-house printing workshop supports screen printing, pad printing, heat transfer, and digital printing to meet various branding needs.

Learn MoreColor & Logo Customization for Silicone Products

You can customize the color of your silicone products based on the Pantone color guide. During the material mixing process, we add FDA-approved color paste to achieve your desired shade. Our standard colors include white, red, green, and gray, and we can also create double-color, marble-effect, or multi-colored molded silicone products upon request.

HaoTian has its own in-house printing workshop, offering a variety of logo and pattern printing options such as silk screen printing, pad printing, heat transfer printing, water transfer printing, in-mold decoration, and digital printing — all designed to enhance your brand visibility and product appeal.Our in-house printing workshop supports screen printing, pad printing, heat transfer, and digital printing to meet various branding needs.

Learn MoreHaoTian International Group (HONG KONG) CO., LIMITED specializes in creating custom silicone products with branded logos that help your company stand out. Whether you’re looking for promotional silicone merchandise, giveaway gifts, or customized silicone items, HaoTian delivers solutions that resonate with your brand identity.We provide professional logo branding services for the promotional and licensing industries. Our clients include marketing and advertising firms, licensors, licensees, wholesalers, retail chains, gift stores, and product development teams. Together, we supply molded silicone logo products to markets around the world — helping businesses grow their brand presence globally.At HaoTian, we offer more than five different methods to apply your logo or design onto silicone products. Each technique is selected based on your logo’s style and performance needs. [Click here] to explore which printing method is right for your branding goals.

Learn MoreOnce your product’s function and structure are confirmed, selecting the right material becomes essential to achieve optimal performance. HaoTian provides fully customized silicone product services — starting from raw material selection tailored to your specific needs.

Our experienced engineers will recommend the most suitable silicone materials based on your product requirements, whether it involves liquid silicone rubber (LSR) or solid silicone, specific tensile or tear strength, or compliance with industry standards such as FDA, LFGB, or medical-grade certifications. We also support material customization based on preferred brands or special project needs. Learn MoreOnce your product’s function and structure are confirmed, selecting the right material becomes essential to achieve optimal performance. HaoTian offers customized packaging solutions for molded silicone products.We provide one-stop services that go beyond manufacturing — assisting clients with the design, development, assembly, and inspection of packaging. Our packaging options include:PET boxesHead cardsPP bagsZip bagsHanging cardsGift boxesPaper color boxesThese packaging solutions are designed to protect the appearance of your finished molded silicone products and ensure safe transportation.Our dedicated packaging team ensures that every product is delivered to end sellers in top condition, maintaining the highest standards of quality and presentation.

Learn MoreOur silicone products undergo a variety of surface treatment processes, including mechanical grinding, polishing, sandblasting, printing, oil spraying, UV modification, laser engraving, electroplating, and spraying. These treatments enhance the appearance, durability, and safety of silicone products to meet the diverse needs of our clients.HaoTian’s in-house surface treatment capabilities allow us to give your silicone products a distinctive look and texture with multiple options. By applying the right surface finish, you can create a stronger impression on potential customers who value fine craftsmanship and attention to detail.

With over 12 years of expertise in molded silicone products and more than 1,000 successful custom projects, HaoTian is your trusted full-service manufacturing partner — turning ideas into high-quality silicone products ready for market.

We go beyond industry standards, focusing on solving your unique product challenges with speed, flexibility, and precision.

Our in-house tooling workshop is equipped with 6 high-precision CNC machining centers and 3 EDM spark machines, allowing us to independently produce and maintain silicone molds. This ensures faster lead times, lower costs, and more control over quality and project timelines.

We operate 20 compression molding machines, 6 liquid silicone rubber (LSR) injection machines, and 8 advanced co-injection molding machines, supporting a variety of custom silicone molding techniques — including compression, LSR, and multi-color over-molding — to meet complex design and functional requirements.

For finishing and branding, HaoTian has 10+ automated printing and spray lines, and a dust-free packaging workshop, enabling seamless integration of logo application, surface treatment, and customized packaging — all under one roof.

We welcome all custom silicone product requests — whether it’s a new silicone innovation, product development idea, or technical inquiry. Let’s bring your vision to life together.

Customized Service Process That Brings Your Ideas to Life

At HaoTian, our Customized Service Process transforms your silicone product ideas into reality with unmatched efficiency and precision. Whether you’re starting with a simple sketch or a detailed CAD file, our experienced team guides you through every phase — from design and prototyping to mold making, production, quality inspection, and packaging.

Leveraging our comprehensive in-house capabilities — including silicone mold tooling, compression molding, over-molding, liquid silicone rubber (LSR) injection, multi-shot molding, and silicone dripping molding — we deliver tailored silicone products that meet your exact specifications in design, function, material, size, color, logo, and packaging.

Our seamless one-stop solution supports a wide range of industries worldwide, from industrial, residential, commercial to medical applications. With responsive communication and a focus on quality at every step, HaoTian makes custom silicone manufacturing simple, fast, and worry-free — scaling effortlessly to meet your unique business needs.

The 5 Essential Steps to Launch Your New Silicone Project

Custom Needs

When we receive customer requirements, they should include the product name, function, 2D/3D drawings, or physical samples. Our sales and engineering teams will communicate closely with you via email, phone, WeChat, or other channels to fully understand your needs.As we all know, great silicone products are carefully designed—not just produced. Designing with the manufacturing process in mind is the crucial first step to ensure a high-quality molded silicone product. Our experts will collaborate with you throughout the design phase, offering professional guidance to bring your silicone product vision to life with both form and function perfectly balanced.Communication

Our experienced sales and engineering teams engage closely with you to fully understand your ideas and the intended function of the silicone products. We collaborate from the very early stages of custom silicone product design to ensure your vision is accurately captured.Based on your ideas or sketches, we can develop precise 3D CAD files for your review. We also carefully examine your 3D drawings and provide expert suggestions to optimize the design for manufacturability—ensuring a smooth transition from concept to production without compromising quality or functionality.3D Drawing Creation

Through thorough communication, we gain a clear understanding of your needs and provide valuable suggestions to ensure your design meets all production requirements. Our goal is to help create a design that can be manufactured consistently and cost-effectively.Once we reach a mutual agreement on the final design, our skilled engineers will develop precise 3D CAD files to move your project forward with confidence.

Confirmation

After thoroughly reviewing your requirements, we will create or adjust the 3D drawing to perfectly align with both your specific needs and mass production feasibility. Once the final 3D drawing is completed, we will send it to you for careful review to ensure everything meets your expectations. Any necessary revisions will be made promptly before receiving your final confirmation to proceed.

In-House Tooling-Making

Our in-house silicone tooling workshop enables us to respond swiftly to changing customer requirements. With customized CNC tooling and EDM machines, we accelerate the production process while maintaining precision. Having tooling capabilities on-site allows for flexible creation and customization of specialized silicone products—saving you time and reducing costs without compromising quality.Material Selection and Sample Confirmation

We offer a range of material options including Solid Silicone, LSR Silicone, and materials meeting safety standards such as FDA and LFGB. You can choose from various silicone hardness levels and sample colors based on Pantone codes. Our experts will provide professional guidance to help you select the ideal material that perfectly suits your silicone product’s requirements, ensuring quality and compliance from the start.Silicone Mass Production Tooling

Based on thorough communication and sample evaluation, we create precision silicone mass production tooling in our in-house workshop—ensuring high-quality molds tailored to your product specifications for efficient and reliable manufacturing.Silicone Products Molding Production

With over 10 years of experience, our silicone molding services cover everything from solid silicone rubber compression molding to liquid silicone rubber injection molding and epoxy co-injection molding. We specialize in manufacturing a wide range of customized silicone consumer products. Our one-stop manufacturing facility operates at high capacity, dedicated to producing personalized silicone products that meet your scalability and quality requirements.Custom Logo for Branding Services

Your logo is the heart of your brand identity — it’s the first impression your potential customers and partners will have of your business. It sets you apart and makes your company recognizable in today’s competitive market. We offer a variety of logo customization services including textured tooling, screen printing, pad printing, laser engraving, and epoxy coating to help elevate your brand presence. Please provide your logo in PDF or CDR format to get started.We are committed to delivering high-quality products that fully meet your expectations. If you encounter any issues, please feel free to reach out to our sales team or customer service anytime — we’re here to assist you 24/7.

Frequently Asked Questions

Yes, we offer free samples for some of our standard silicone products so you can evaluate the quality before placing a bulk order. For customized items, sample fees may apply depending on the complexity and tooling involved — but these fees are often refundable once your order is confirmed. Feel free to contact us with your request, and our team will guide you through the sample process promptly.

No worries at all! If you’re not sure about the fabric or material details, our experienced team is here to help. Just share with us the purpose, usage environment, or any reference product you have in mind — and we’ll recommend the most suitable silicone material, hardness, and other technical specifications for your project. We’re committed to making the development process simple and stress-free, even if you’re starting from just an idea.

We primarily use high-quality, food-grade silicone that complies with FDA and LFGB standards, ensuring safety, durability, and eco-friendliness. Depending on the application, we also offer medical-grade silicone, liquid silicone rubber (LSR), and high-consistency rubber (HCR). All materials are carefully selected to match the specific functional and regulatory needs of each product — whether it’s for baby items, kitchenware, electronics, or industrial components. If you have special material requirements, we’re happy to accommodate them.

Yes, we are a professional silicone product manufacturer with over 12 years of experience. All of our production processes — from mold making to packaging — are completed in-house at our factory in China. We specialize in OEM and ODM services, and we’re fully equipped to turn your custom designs into high-quality silicone products. Whether you provide a concept, drawing, or sample, we can work closely with you to bring your ideas to life efficiently and cost-effectively.

2D,3D drawing, and the specific requirement.

Yes, absolutely! We support both custom logos and custom molds. Whether you need branding on existing products or a completely new mold design, our team can help bring your ideas to life with professional OEM/ODM support.

Customers will need to pay for a mold if you have a custom design. And the mold will belong to the customer.

Yes. Sample mold only could use for sample making. When you need to run for mass production, a mass production mold is requested.

For bulk orders we ship it by sea or by air, For small orders, we ship by DHL, FedEx, TNT, or UPS

Still Have Questions?

If you don’t find the answer you’re looking for in our FAQ, feel free to reach out to us anytime — we’re here to assist you and will get back to you promptly.