A survey by Packaging World Survey (2026) indicates that consumer purchasing behavior depends on branded packaging and it is rated at 78%. In the case of silicone bottles that is a $2.3 billion category now, the printing of logos with custom made logo is not an option anymore; it is the difference between a generic reusable bottle and the icon that defines a lifestyle. Hydro Flask and Owala have a premium of 40-60 in a unique and durable branding on pliable silicone surfaces. It is a global buyer branding guide to OEM, which offers consumers the information necessary to choose the printing methods that last 1,000+ dishwasher cycles, comply with FDA standards, and offer a high value of perception. Silk-screen to laser-etched, this is a list of the sure ways to change the execution of the custom silicone bottle logos.

Understanding Silicone’s Printing Challenges & Advantages

The surface of silicone is non porous and elastic (Shore A 40-70) and less penetrable to regular inks but is more penetrable to specialized processes. Key traits:

- Heat Resistance: Can withstand 200 deg C without deformation.

- Flexibility: Extension 500 percent without cracking without breakage of print layers.

- Chemical Inertness: Water based inks repel this type; adhesion is necessary of silicone based.

The manufacturers of professional silicones (OEM) respond to these with curing (high temperature or plasma) and pre-treatments (plasma or primer). The payoff? Branding that is subjected to daily flexing, UV rays, abrasion- much better than plastic label peeling and custom silicone bottle

Common Logo Printing Techniques for Silicone Bottles

a. Silk Screen Printing

Promotional and retail bottle horse. Ink is pressed through a fine mesh on the silicone, and baked in 150-180 deg C.

- Colors: 6-spot Pantone-matched.

- Detail: 0.1 mm line width minimum

- Applications Full wrap graphics, team logos, event merchandize.

Advantages: inexpensive (0,15-0,40 could be used per color), bright paint.

Cons: Microcracking can occur in high-stress parts after 500 or more flex Reps.

Perfect suited to 5,000 and above units in frequencies targeting gyms or festivals.

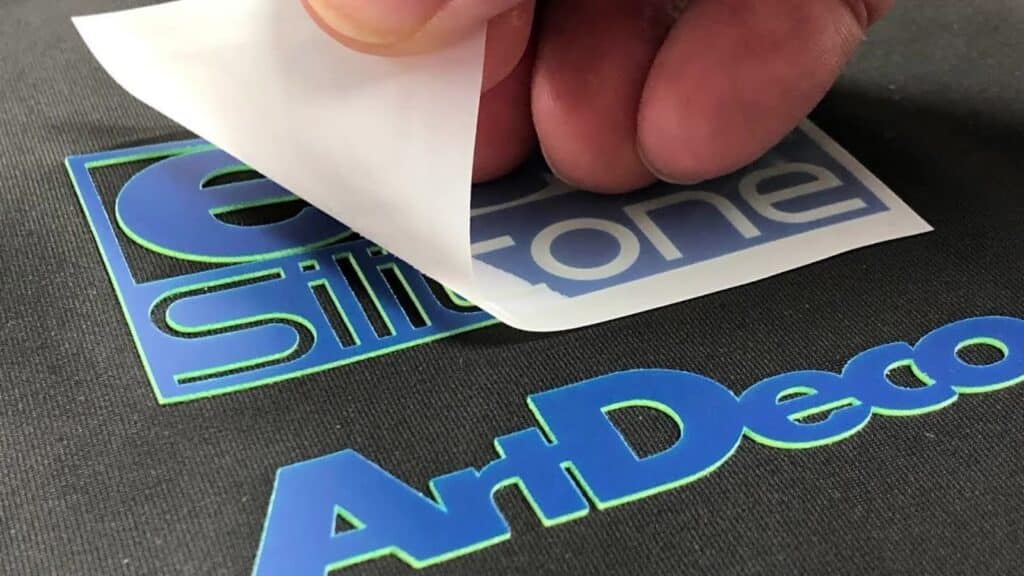

b. Heat Transfer Printing

Heat press (180degC, 30 seconds): A film with pre printed images is put on the silicone surface and the ink is melted through heat.

- Determination: 0300 DPI.

- Colors: Full CMYK Full white underlay.

- Summary: Gloss or matte textures are available.

Advantages: smooth color gradients (there are no mesh lines).

Disadvantages: Not as durable on collapsible areas (peel risk of 300 cycles)

Best on limited edition retail design work that has complicated artwork.

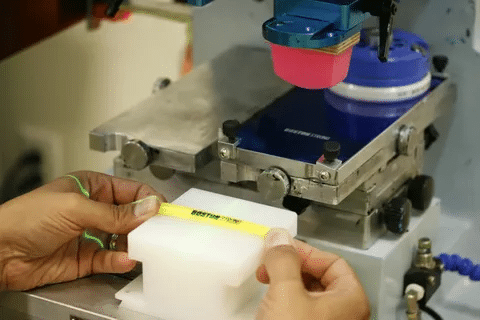

c. Pad Printing (Tampo Printing)

An ink is absorbed on a plate by a silicone pad nudged and transferred to contoured surfaces.

- Logo Size: 3-50 mm diameter

- Surface: Bottle caps, grip concave areas, textured areas.

- Colors: 1-4 spot colors

Advantages: Adheres to 3D shapes, high accuracy of registration.

Cons: Reduced thickness of dark silicone; not greater than 2 mm.

Necessary to tiny, minute scribbles on ergonomic handles.

d. Laser Engraving

Fib 4 or CO2 lasers cut a micro-layer of silicone (0.05-0.2 mm depth), and make it permanent contrast.

- Precision: +-0.01 mm accuracy

- Effect: Dark colour of carbonized or tone-on-tone.

- Speed: 1,000 bottles/hour

Advantages Zero ink, dishwasher permanent, environmentally friendly.

Disadvantages: black and white only; cannot be used in color logos.

Penny pricing Perfect on high-end minimalist brands (e.g. on matte black with M monogram).

e. Embossed & Debossed Logos (3D Branding)

Molded in–logo belongs to tool steel cavity.

- Height/Depth: 0.3-1.0 mm

- Choice: Raised (embossed), recessed (debossed).

- Tactile: Premium hand-feel

Advantages: Unbreakable, does not add up to the cost of the mold.

Cons: Mold modification would be necessary (costs are between $800-2,000)

Luxury wellness and corporate gift standard.

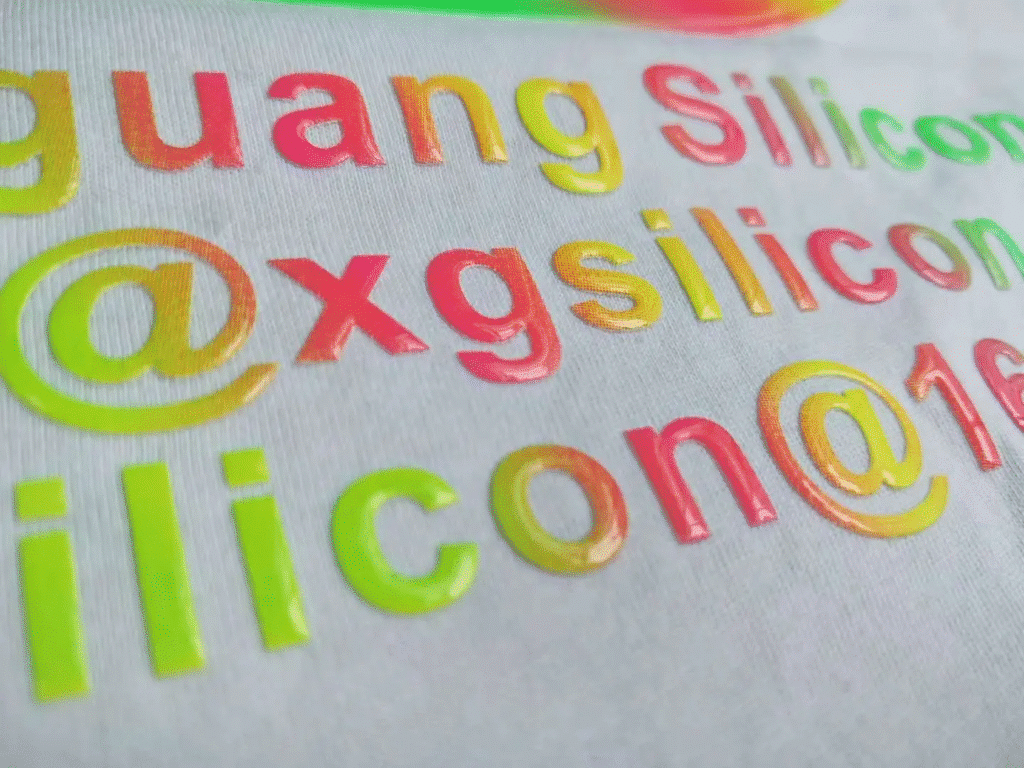

f. Color Filling for Molded Logos

Approved pigment Debossed logos are cured and filled with FDA approved liquid silicone pigment.

- Colors: Pantone-compatibility, metallic, glow in dark.

- Observe: Flushed or slightly elevated.

- Endurance: 2,000+ flex wear life.

Advantages: bright contrast, smooth combination.

Cons: Adds 3-5 days to lead time

Embosses/debosses high-view branding designs.

Comparing Techniques – Which One Fits Your Brand

| Method | Durability* | Color Options | Texture | Ideal For | Cost (10K units) |

| Silk Printing | Medium | High | Smooth | Promotional bottles | $0.20–$0.50/unit |

| Heat Transfer | Medium | Very High | Glossy | Retail designs | $0.40–$0.80/unit |

| Pad Printing | Medium | Limited | Flexible | Curved surfaces | $0.15–$0.35/unit |

| Laser Engraving | Very High | None | Matte | Premium minimalism | $0.30–$0.60/unit |

| Embossed/Debossed | Very High | Optional | Textured | Luxury branding | $0 (mold cost) |

| Color Filling | Very High | High | Flush | High-visibility 3D logos | +$0.25/unit |

*On the basis of 1,000 dishwasher loads + daily flexing.

OEM Branding Best Practices

- Demand FDA 21 CFR 177.2600 and RoHS certificates Ink Compliance.

- Pre-Production Proofing: Material (physical sample) required: check Pantone delta <2.0.

- Adhesion testing: The ASTM D3359 cross hatch (5B) test.

- Placement Consistency: Jigs guarantee +-1 mm logo localization amongst SKU.

- Curing Validation: The complete cross-linking is determined by FTIR spectroscopy.

Haotian Silicone has a laboratory of its own that conducts 72 hours of boil tests on each shipment.

Design Tips for Strong Brand Identity

- Scalability: Design logos should be easy to read at 15 mm and 50 mm high.

- Negative Space: 2mm bleed along flex zones.

- Color Psychology: Eco-brands: Earth tones, fitness: Neons.

- Sleeve Synergy: Neoprene carrier graphics must be matched to bottle print.

Basic, high contrast icons do better than multi-effect crests on curved silicone.

Conclusion – Turning Function into Brand Value

Silicone bottles printed with custom logos combine both durability and design into one product, which lives in the hands of consumers- and in their minds. It could be silk-screened color to sell in large numbers or laser-etched permanence to sell in small numbers, but the appropriate technique will enhance brand equity and ensure safety and sustainability standards.

In search of credible OEM logo printing of your silicone bottle line? Haotian Silicone has offered high end branding solutions of laser etching as well as full colour printing, to international brands that want durable, beautiful and environmental friendly solutions. Sample and technical specifications will be made available on request.