Certified Excellence: Unveiling Our Accolades

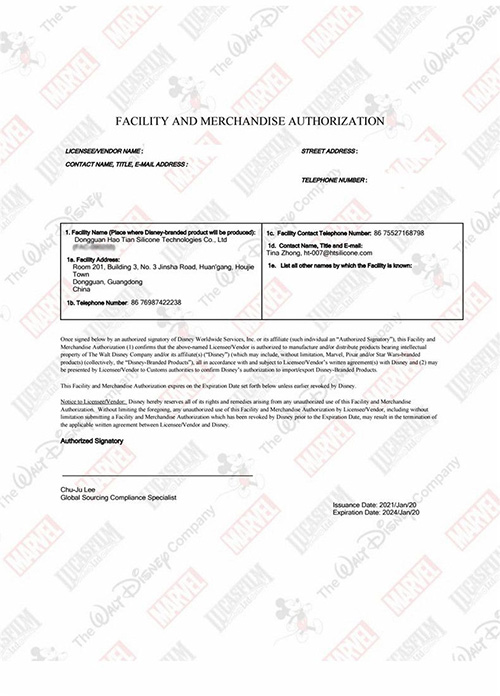

Disney FMAM

The Disney FAMA (Factory Authorization and Manufacturing Authorization) certificate is a compliance program initiated by Disney to ensure that products featuring Disney characters or intellectual properties are produced under ethical and legal conditions. This authorization is typically granted to manufacturing facilities that meet Disney’s stringent standards for labor practices, workplace conditions, and overall business ethics.

To receive the Disney FAMA certificate, a factory must pass an audit conducted by an independent third party approved by Disney. This audit assesses various aspects, including working conditions, employee rights, environmental impact, and adherence to Disney’s Code of Conduct. Once certified, the factory is authorized to produce Disney-branded products, indicating that they align with Disney’s values and standards.

In summary, the Disney FAMA certificate is a testament to a manufacturer’s compliance with Disney’s ethical and quality standards, providing assurance to consumers and licensors that the products are produced responsibly and ethically.

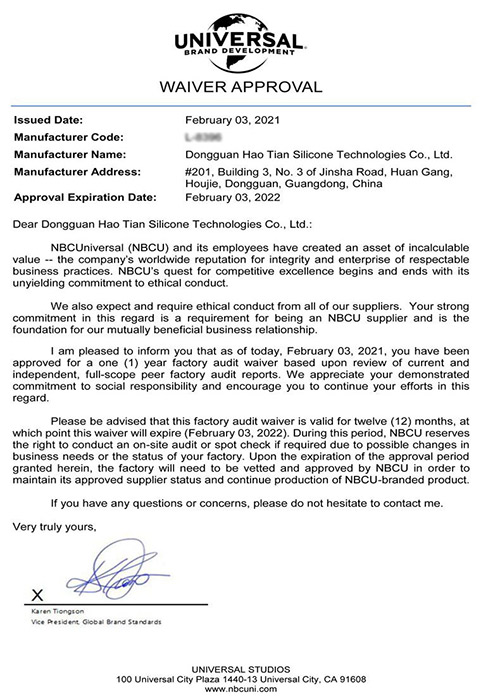

Universal Studios Certificate

Universal Studios Certificate” can refer to a certification or approval granted by Universal Studios, a major film studio and theme park company. However, without specific context, it’s challenging to provide precise information about what this certificate entails.

In the context of licensing or partnerships with Universal Studios, a “Universal Studios Certificate” might indicate that a product, service, or entity has received approval or authorization from Universal Studios. This could involve meeting certain quality standards, adhering to licensing agreements, or being deemed suitable for association with the Universal Studios brand.

IOS 9001

ISO 9001 is an international standard for quality management systems (QMS). It outlines the criteria a company or organization needs to meet to ensure that their products and services consistently meet customer requirements and that the quality is continually improved.

Key aspects of ISO 9001 include a strong customer focus, the involvement of top management, a process approach to quality management, and ongoing improvement. Companies that achieve ISO 9001 certification demonstrate a commitment to delivering quality products and services while continuously striving for improvement in their processes.

This certification is widely recognized and can enhance a company’s reputation, opening up opportunities for business partnerships and demonstrating a dedication to quality management on a global scale.

IOS14001

ISO 14001 is an internationally recognized standard for environmental management systems (EMS). This standard sets out the criteria for an organization to establish an effective environmental management system, providing a framework to identify, monitor, and control environmental aspects and impacts.

Key principles of ISO 14001 include a commitment to compliance with legal requirements, pollution prevention, and a focus on continuous improvement in environmental performance. Organizations that obtain ISO 14001 certification demonstrate their commitment to minimizing their environmental footprint and managing environmental risks.

This certification is valuable for companies seeking to integrate environmental considerations into their business operations, enhance their environmental performance, and meet the expectations of stakeholders concerned about sustainable and responsible business practices.

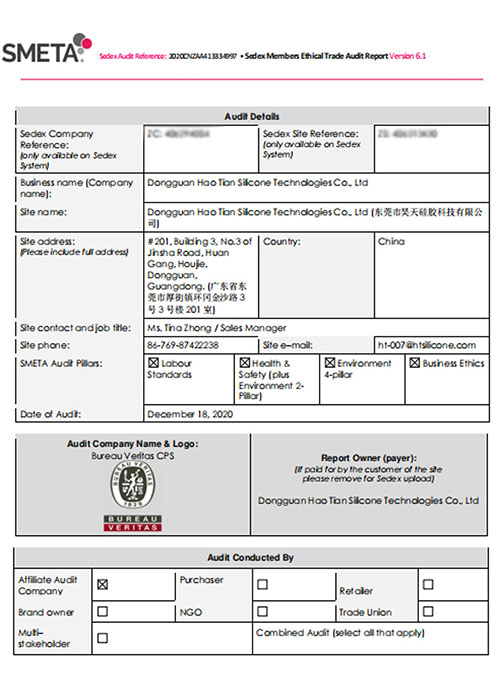

SMETA

The SMETA (Sedex Members Ethical Trade Audit) certificate is a widely recognized ethical audit, specifically designed for suppliers and organizations in the supply chain. Sedex, the organization behind SMETA, is a not-for-profit membership organization dedicated to driving improvements in ethical and responsible business practices in global supply chains.

The SMETA audit focuses on four key pillars:

Labor Standards: This includes assessing working conditions, employment contracts, working hours, and the overall treatment of workers.

Health and Safety: Evaluation of health and safety policies and practices within the workplace.

Environmental Standards: Examination of environmental practices and compliance with relevant regulations.

Business Ethics: Assessment of business integrity, including anti-bribery and corruption measures.

The goal of the SMETA certificate is to encourage and enable transparency and ethical business practices throughout the supply chain. It provides a common auditing methodology, reducing duplication and inefficiency in the audit process. Companies that obtain the SMETA certificate demonstrate their commitment to ethical trading and responsible business conduct.

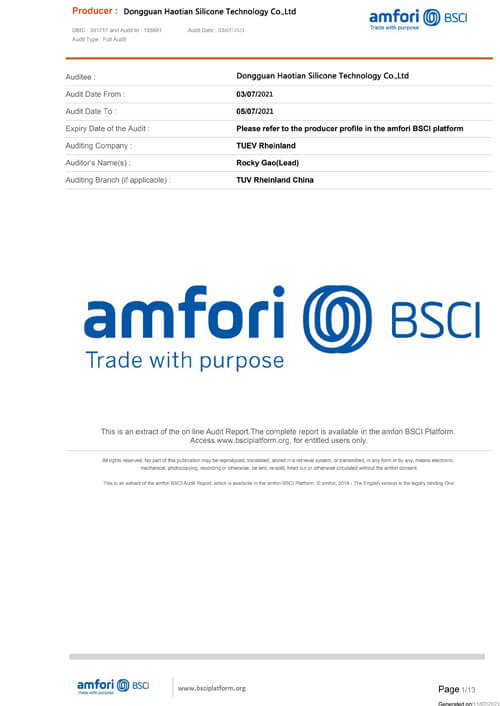

BSCI

The BSCI (Business Social Compliance Initiative) certificate is a certification for companies committed to improving working conditions in their global supply chains. The BSCI is a European initiative that aims to promote social compliance and improve labor conditions in manufacturing and trading companies worldwide.

Key components of the BSCI certification include:

Social Standards: BSCI audits assess compliance with fundamental labor rights, including fair remuneration, safe working conditions, and the prohibition of child labor and forced labor.

Environmental Standards: While primarily focused on social compliance, BSCI audits may also touch upon environmental aspects, encouraging companies to consider sustainability in their operations.

Management System: BSCI certification encourages the establishment of effective management systems for social compliance, ensuring continuous improvement and accountability.

Companies that obtain the BSCI certificate signal their commitment to ethical and socially responsible business practices. This certification is recognized globally and is often sought after by businesses looking to demonstrate their dedication to fair labor practices and social responsibility.

One-Stop Silicone Product Solution

Haotian is with you every step of the way when it comes to your silicone supply, from bringing your concept to fruition to sending out your cleaned and packaged goods. Our facility is equipped with 8 assembly lines that are 40 meters long and strict 5S management and quality control protocols are enforced on-site.