Introduction: Why Custom Silicone Design Matters for Brands

In the present competitive world, where consumers desire exclusive and high quality products that communicate their values, custom silicone products can give a brand an excellent means to differentiate themselves. It can be a branded silicone wristband carry it to an event, it can be a bespoke silicone phone case with this logo on it, or any other special rubber gasket needed to mount on an industry device, these products appear to be durable, flexible and customizable that would help enhance brand recognition and retention. Being the representative of Dongguan Haotian Silicone Technology Co., Ltd., a company that was established in 2015 and deals with multi-color and complex silicone solutions, I have assisted thousands of brands through the process. The entire in-house design-to-deliver package has allowed us to work with such icons as Disney, Universal Studios, and Huawei and demonstrate that a considered development of silicone products can make your products stand out.

The custom silicone design is not only a question of the aesthetics, it is also a question of the ability to provide optimal, safe, and sustainable products that reflect the brand narrative. In the case of OEM silicone products, it is essential to know the process of idea to product production to prevent expensive errors and to meet the standards, such as FDA or LFGB. This guideline will take you through the silicone product development process step by step based on our experience with patented multi-color integrated molding and certifications like ISO9001, ISO14001, SEDEX and BSCI. When you are through, you will know how to create your own silicone to promote a brand successfully, making the idea a market hit.

Section 1: Step 1 — Define Your Product Idea and Purpose

The basis of a successful custom silicone product begins with a crystal-clear idea and purpose. Before you start drawing sketches or specifications, remember to ask yourself What problem does this solve? Who is the target user? As an example, when creating a completely personalized silicone bottle in an environmentally conscious fitness company, the designer must think of how it should be leak-proof, lightweight, and easy to hold. We have had successful brands in our projects where a brand begins with a detailed brief which includes size (e.g. 500ml capacity), shape (ergonomic curve), and functionality (collapsible to be portable).

Warm-up: Brainstorming: https://phonecase.com Write down some of your features such as colour schemes, textures or integrations (e.g., a strap to a phone case). Check with what products are already in the market or with competitors to hone your own idea with custom silicone. This action in the design of silicone products avoids overcomplication in the future- simple designs tend to form more and are less expensive. When you have a clear idea, tell us about your silicone product idea to us and we will provide you with an initial opinion on whether your product is feasible or not to make sure that it is not out of touch with the realities of the production.

Section 2: Step 2 — Work with an Experienced Silicone Manufacturer

The main reason to collaborate with a trusted OEM silicone manufacturer at the inception of the design is to avoid traps and maximise the design. At Haotian Silicone, we cooperate since the very beginning, providing knowledge in the field of material science, engineering, and compliance to perfect your vision. Find a silicone manufacturing collaborator that has good credentials- Disney and Universal factory audits, BSCI and SEDEX certifications ensure ethical and of high quality production.

A mature silicone product vendor will think about whether your idea can be made and make recommendations to improve it such as adding a little more (or a little less) wall thickness to eliminate defects. The step is necessary because it keeps your custom silicone project on budget and schedule, particularly when partnering with a manufacturer of OEM silicone new to its brands. Our early quotes are based on a volume, complexity, and specification, which can assist you to decide on the small-scale prototyping or full scale production.

Section 3: Step 3 — 3D Design and Engineering Development

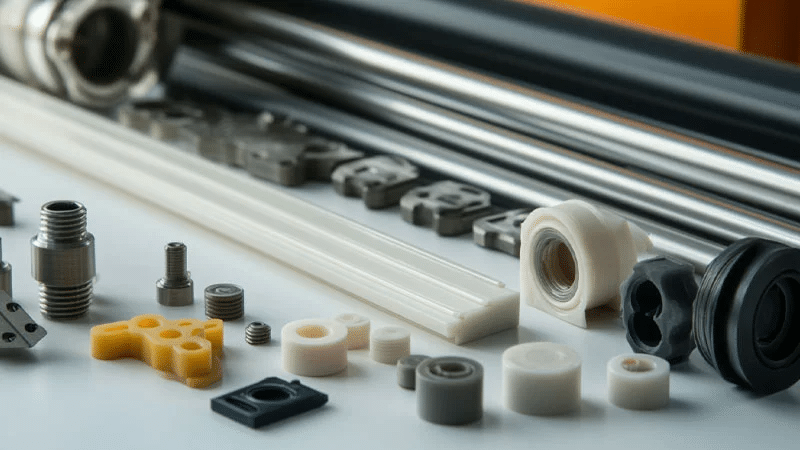

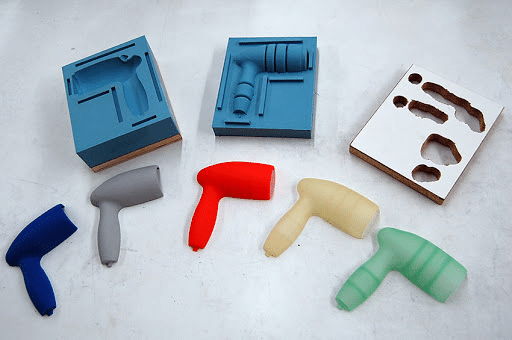

As the idea is firmly formed, the 3D design and engineering development is the next step here, where digital models are created based on ideas. Our engineers produce CAD silicone models using software such as SolidWorks which include details such as undercuts, textures or multi-part assemblies. In the case of branded silicone wristband, we would deboss the logo, but not too deeply so that the structure becomes weak.

It is a silicone design step that takes into consideration material shrinkage (usually between 1-3 per cent silicone) and parting lines to release moulds. We do simulations to check flexibility and fit that is important with products such as custom silicone phone cases which need to fit snugly. The prototype validation follows, and it is usually done through 3D printing a resin mockup to be reviewed practically. In our case, this type of silicone prototype development is very early and saves time in the subsequent stages.

Section 4: Step 4 — Select the Right Silicone Material

The performance can determine or break your product, hence, choose according to its performance requirements. We have materials such as Liquid Silicone Rubber (LSR) which is precise and soft and is used in medical grade material and High Consistency Rubber (HCR) which is tough in industrial gaskets. Silicone used in food grade and being FDA and LFGB compliant, is used in kitchenware such as custom silicone mats, so that no toxins are leached.

The most important values are hardness on Shore A scale (20A of soft grips, 60A of hard seals), temperature resistance (-60degC to 230degC) and transparency. With branded products, it is possible to add appeal using custom color silicone via Pantone matching, and perfect gradients can be achieved using our patented multi-color process. The chosen silicone material is safe, stable, and matches the ethos of your brand, such as the formulations of eco-friendly lines.

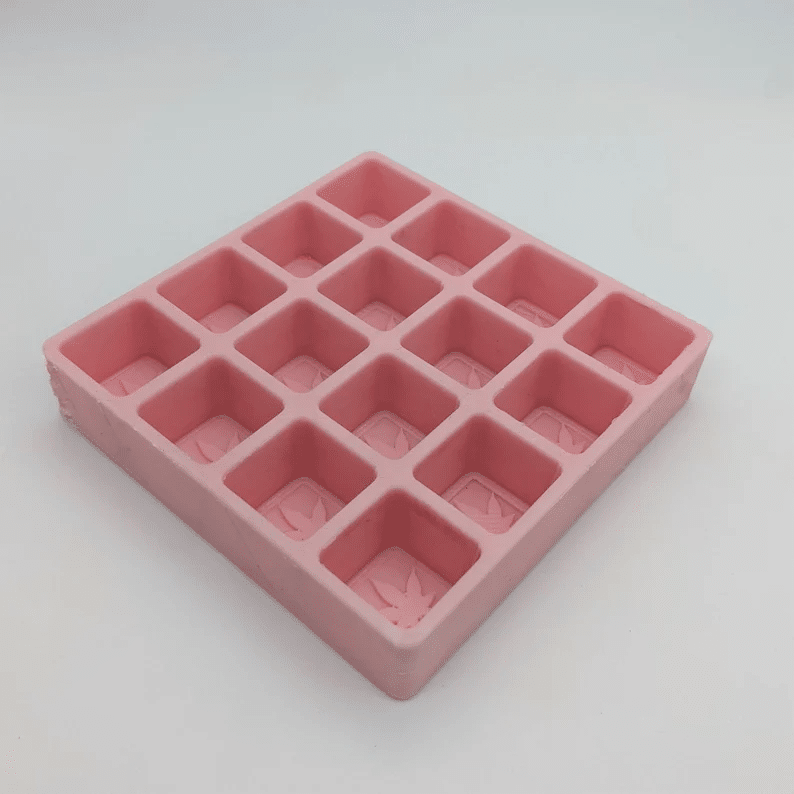

Section 5: Step 5 — Mold Design and Fabrication

Design and fabrication Mold design and fabrication transform your digital model into a production tool and require accuracy to ensure consistent results. CNC machining or EDM is used to create steel molds but with emphasis paid to venting to avoid traps of air and the positioning of gates to ensure smooth flow. In complicated form, such as a design of a bespoke silicone container with threads, multi-cavity arrangements are made in the process of designing the moulds to be efficient.

Such factors as the ejection mechanisms and cooling channels are taken into account to optimize cycle times. We have silicone mold making experience with utility patents on overmolding multi-material parts. This is an expensive step of investment silicone tooling, but it is worth the cost, as lifespan molds last for hundreds of thousands of cycles, which is very desirable in OEM manufacturing.

Section 6: Step 6 — Sample Production and Testing

Your design is tested and validated in sample production and testing before it is scaled. Our T1 samples are made using the new mold and cured through vulcanization to give strength. In the case of a custom silicone phone cover, we would be doing a test fit on real devices, such as checking the flexibility and grip.

Silicone sample testing involves dimensional inspection, hardness inspection and functional tests such as drop tests. Where corrections must be made, such as adjustment of color or thickness, we cycle easily. This pro-testing provides that the product is within specifications, mass production problems will be avoided and brands will have confidence.

Section 7: Step 7 — Mass Production and Quality Control

Approved samples are then mass produced (relying on such processes as injection or compression molding to be efficient). Silicone cures when subjected to pressure and heat creating strong products- our multi-color technology incorporates colors without addition marks.

There is a continuous monitoring of silicone quality: In-line checks of defects, post-molding trimming, and tensile strength and compliance checks. In case of food-grade products, we guarantee the FDA standards. This is a silicone mass production stage, which falls under our ISO9001 system and it provides uniform OEM silicone production ranging between thousands and millions.

Section 8: Step 8 — Packaging, Branding, and Final Delivery

The product is finalized through packaging and branding which makes the product more attractive to the shelves. Our boxes are made using inserts to protect products, using sustainable brands with eco-materials. Labeling or wrapping yourself strengthens your identity.

The last quality control is followed by the delivery of silicone products- packed in a manner safe to be transported worldwide. Our logistics will guarantee a delivery on time, and the process of providing the custom silicone packaging and delivery will be finished.

Section 9: Expert Tips for a Successful Custom Silicone Project

In our experience, early communication is central to the success of custom silicone projects: Ensure confirm drawings prior to tooling to eliminate delays. Ask 3D renderings to be accurate, and negotiate on logo placement in advance to be printed best.

Select a factory that offers end-to-end service such as that of ours, i.e. design tips on silicone, design, and manufacture. In the case of brands, develop such features as antimicrobial coating. Adopt tailor-made silicone projects; in the right combination, the versatility of silicone creates infinite potential of safe and durable products.