The global market in reusable water bottles is going to exceed 15 billion by 2026, with the increase of consumers moving towards compact, zero-waste hydration bottle selections by 72 percent (Euromonitor 2025). Bans on EU and California are phasing out single-use plastic bottles, which contribute 1.5 million tons of yearly ocean pollution. The most suitable alternatives have been the emergence of collapsible silicone bottles that can be reduced to the size of a pocket (less than 150 g), are less than 5 years old, and weigh less than 150 grams. This sustainable hydration technology is a combination of material science and sustainability, and it can provide brands with the opportunity to create a product that can be scaled, is eco-credible and meets the requirements of the circular economy. The collapsible silicone bottles are transforming how people drink on the move through their airport retail outlets to outdoor gear.

What Makes Collapsible Silicone Bottles Unique

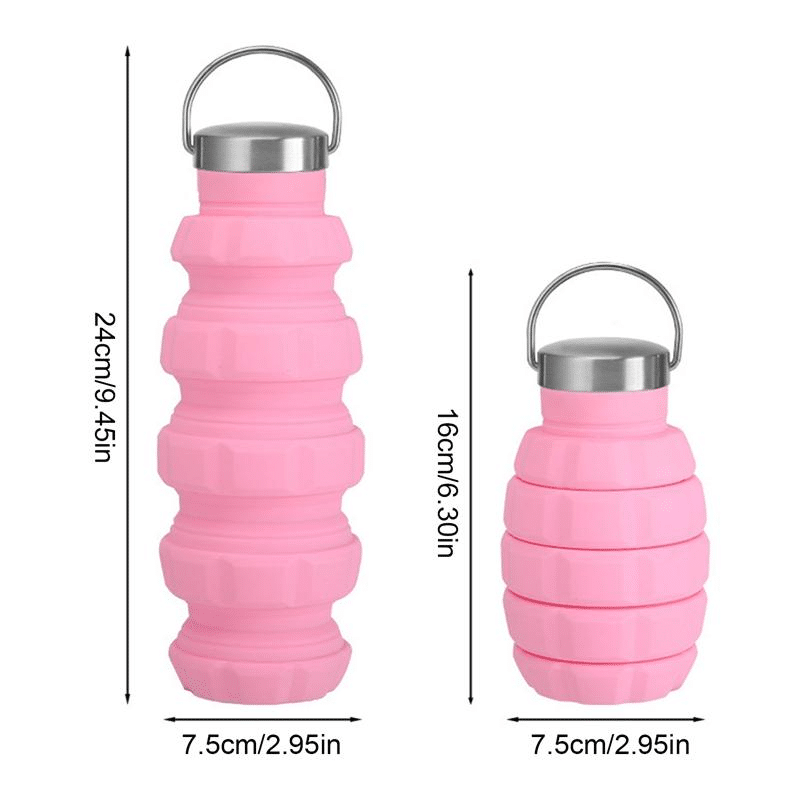

A collapsible silicone bottle is a flexible accordion-shaped or spiral shaped body, composed completely of food grade silicone. At full it contains 500-750 ml rigidly, at empty it closes to 20-30 per cent of its volume. Key components include:

- Body 1.5-2.0 mm platinum-cured silicone walls.

- Base Ring: Tritan or rigid PP because of upright stability.

- Top: Screw or flip-cap bleeding seal that has a silicone gasket.-Weight: 120–180 g (vs. 400 g stainless steel)

Its design is that of a one-handed operating product capable of doing 50,000 and more compression cycles without cracking it thus making it the ultimate foldable water bottle to be used in traveling, hiking, or gym bags.

The Material Advantage – 100% Food-Grade Silicone

Silicone is better than plastic and metal in flexible parts. Addition-cure silicone has platinum-cured silicones that do not contain curing byproducts and result in:

| Property | Performance |

| Temperature Range | –40°C to +250°C |

| Migration | <0.5 mg/dm² (FDA 177.2600) |

| Hardness | Shore A 50 (optimal flexibility) |

| Tear Strength | 40 kN/m |

It is LFGB certified, BPA-free, and odourless and therefore safe enough to hold a hot coffee or frozen smoothie without leakage. Silicone materials rebound their shape after hitting unlike PET plastic (warps more than 70degC) or aluminum (easy to dent).

Functional Benefits That Redefine Portability

- Space Saving: A 650 ml bottle folds into the height of 9 cm – fits in jacket pockets.

- Weight: 65 weight reduction as compared to stainless steel counterparts.

- Compliance: TSA: Permitted to pass empty bottle; fill after checking in.

- Cleaning: Wide-Mouth (45 mm) + dishwasher-safe.

- Durability: Meets 1.5 m on concrete (6 faces) drops.

Gym-goers document 40 percent more carry compliance as compared to rigid bottles (Nielsen survey).

Design & Innovation Trends

2026 designs push boundaries:

- Compromise Bodies: Compromise and still be drinkable Best of both worlds Bodies.

- Integrated Carabiners: 50 kg Anodized aluminum loops.

- Multi-Cap Systems: Alternate between the straw or spout lids or wide-mouth lids.

- Smart Indicators: Built-in hydration alert LEDs (Bluetooth());

- Gradient Matte Finishes: Soft-touch colors with sunrise or ocean fade colors.

In the 2025 Packable line, Hydro Flask sold 1.2 million in the first quarter, demonstrating that the trend in travel accessories is towards silicone.

Sustainability & Environmental Impact

Lifecycle Comparison (650 ml bottle, 3-year use):

| Metric | Collapsible Silicone | PET Plastic | Stainless Steel |

| CO₂ Footprint | 0.9 kg | 2.4 kg | 3.1 kg |

| Water Usage | 12 L | 28 L | 45 L |

| Waste Generated | 180 g (recyclable) | 1,095 g | 400 g |

| Replacements Needed | 0 | 1,000+ | 0 |

A single silicone bottle will eliminate 1,000 or more plastic bottles in landfills. воїщΡolst enters 92% of the materials into recycling (e.g. TerraCycle).

Customization & Branding Opportunities for OEM Buyers

China capabilities in its OEM silicone manufacturer:

- Color: Pantone range All + metallic flake additives

- Branding: 357.deg debossing (0.5 mm deep), laser marking, heat-transfer publications.

- Textile: Ribbed grips, frosted windows, or pearl finishes.

- Packaging: Fill up of custom kraft tubes using hang-tag or blister cards.

- MOQ Flexibility: Constitute 500 mixed colors.

The collapsible bottle with the embossed panda logo of MINISO sold 2.5 million in 2024.

Market Outlook – Why Collapsible Bottles Are the Future

- Travel Retail: Sandwiches: Duty-free sales increased 38% YoY (IATA).

- Fitness Sector: Gym memberships +12% world wide (IHRSA)

- Gen Z Preference: 81 per cent of them focus on the foldable design (Deloitte).

- OEM Growth: The Chinese factories indicate 45 percent growth on collapsible orders annually.

In the year 2026, collapsible formats will take 35 percent of the silicone bottles.

Conclusion – Compact, Reusable, and Future-Ready

Silicone bottles are collapsible, extremely portable, secure, and sustainable like no other – when small enough to fit into the lifestyle of modern life, growing the brand influence. Their light weight food grade construction, innovative design and eco-credentials make them the ultimate portable hydration solution and the best custom silicone bottle

Need quality OEM solutions to collapsible silicone bottles? Cooperation with Haotian Silicone- the company provides certified, environmentally friendly, and fully customized designs to international brands. Send the US your prototype of 2026 line.