Custom Silicone Bottles Manufacturer — Safe, Flexible & Sustainable Solutions

Design your own silicone bottles for travel, sports, or baby feeding with Haotian Silicone. We provide FDA-approved, leak-proof, and fully customizable bottles ideal for retail and promotional use.

Why Choose Our Silicone Bottles

Custom Design & Private Label

We offer OEM/ODM customization, including size, color, mold design, and full logo branding options.

100% Food-Grade Silicone

All bottles are made from FDA & LFGB certified materials, ensuring safety for food, baby, and cosmetic use.

Durable & Leak-Proof Structure

Each bottle is designed with precision molding technology for durability, flexibility, and a tight seal that prevents leaks

Wide Range of Applications

Suitable for travel, sports, baby feeding, and personal care, meeting the needs of both consumer and industrial brands.

Fast Sampling & Reliable Delivery

Quick prototype turnaround and on-time mass production with global logistics support.

Strict Quality Control

Every silicone bottle goes through multi-step inspection to ensure smooth finish, accurate color, and consistent quality.

Custom Design & Private Label

We offer OEM/ODM customization, including size, color, mold design, and full logo branding options.

100% Food-Grade Silicone

All bottles are made from FDA & LFGB certified materials, ensuring safety for food, baby, and cosmetic use.

Durable & Leak-Proof Structure

Each bottle is designed with precision molding technology for durability, flexibility, and a tight seal that prevents leaks

Wide Range of Applications

Suitable for travel, sports, baby feeding, and personal care, meeting the needs of both consumer and industrial brands.

Fast Sampling & Reliable Delivery

Quick prototype turnaround and on-time mass production with global logistics support.

Strict Quality Control

Every silicone bottle goes through multi-step inspection to ensure smooth finish, accurate color, and consistent quality.

Explore Our Custom Silicone Bottle Range

From collapsible travel bottles to baby feeding and sports bottles, Haotian offers a variety of silicone bottle styles to meet your market needs. Each model can be customized in color, capacity, shape, and surface finish.

Custom Silicone Baby Bottle – BPA-Free Soft Nipple Feeding Bottle for Newborns

Custom Silicone Travel Bottles – 2-in-1 Refillable Shampoo Containers with Massage Scrubber Design

Custom Silicone Travel Toiletry Bottles – Leak-Proof Refillable Cosmetic Containers with Clear Bag

Custom Silicone Water Bottle – Collapsible Reusable Travel Cup with Lid and Carabiner

Custom Silicone Water Bottle – Foldable BPA-Free Collapsible Travel Bottle with Stainless Steel Lid

Custom Silicone Water Bottle Boot – Anti-Slip Protective Bottom Sleeve with Bow Design

Tailor Every Detail of Your Silicone Bottle

- Material & Color Options

- Logo & Surface Techniques

- Packaging & Branding Solutions

Material & Color Options

At Haotian Silicone, we offer a wide range of premium silicone materials to meet your product’s safety and performance needs — including food-grade, medical-grade, eco-friendly, and high-temperature silicone.

All materials are BPA-free, FDA/LFGB compliant, and available in different hardness levels.

We also provide custom color matching based on your Pantone code, with options such as solid, translucent, swirl, marble, or glow-in-the-dark finishes.

Every pigment is non-toxic and RoHS/REACH compliant, ensuring your products look great and meet global quality standards

Logo & Surface Techniques

Haotian Silicone offers a variety of logo and surface customization options to make your products stand out. We support debossed, embossed, color-filled, screen printed, and laser-engraved logos — each crafted with precision molds for lasting detail and quality. Our advanced finishing options include matte, glossy, and textured surfaces, giving your products a distinctive touch and premium appearance. All pigments and coatings are eco-friendly, durable, and compliant with international safety standards.

Packaging & Branding Solutions

At Haotian Silicone, we go beyond manufacturing by offering complete packaging and branding solutions for your silicone products.

From custom retail boxes, header cards, and hang tags to printed logos, barcodes, and eco-friendly packaging, we help you deliver a product that’s ready for the market.

All packaging can be fully customized with your brand logo, color theme, and product details, ensuring consistency and professional presentation for retail or e-commerce.

Our Successful OEM Silicone Bottle Projects

Take a look at how we’ve helped global brands design, mold, and produce silicone bottles that match their identity and market demand.

Custom Silicone Bottle Manufacturing Process

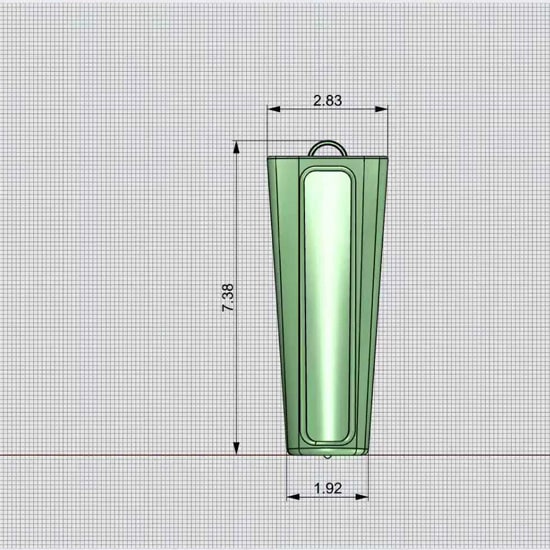

Design & Concept Confirmation

Our design team turns your ideas into 3D models and technical drawings, confirming bottle shape, size, cap type, and accessories before production.

01

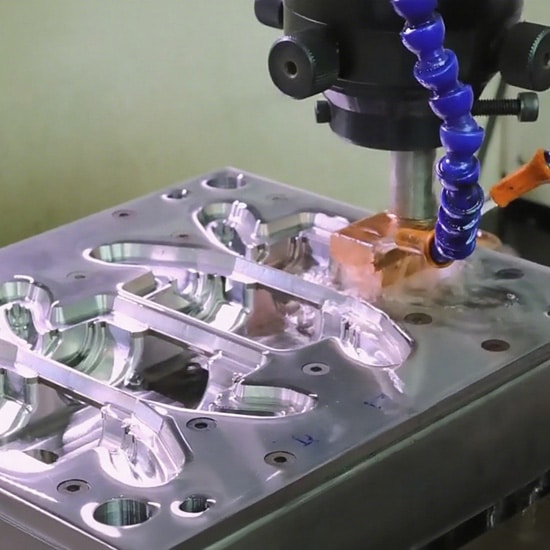

Mold Development

Precision molds are created using CNC machining to ensure accurate dimensions and high consistency for mass production.

02

Raw Material Selection

We use 100% food-grade platinum silicone, certified by FDA and LFGB, ensuring safety, flexibility, and eco-friendliness.

03

Molding & Shaping

Each bottle is formed through high-temperature compression or LSR molding, achieving excellent elasticity, leak resistance, and durability.

04

Surface Finishing

Custom surface options include matte, glossy, or textured finishes, plus printing or embossed logos for brand differentiation.

05

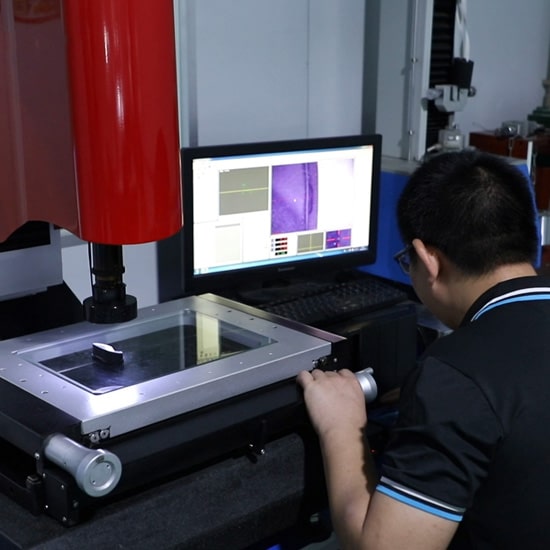

Quality Control & Testing

Every bottle undergoes leak tests, heat resistance checks, and visual inspections to guarantee top quality and uniform appearance.

06

Packaging & Branding

We offer custom box packaging, hang tags, sleeves, and private labeling, helping clients build a cohesive brand presentation.

07

Delivery & After-Sales Support

Finished products are shipped via sea, air, or express delivery. We provide tracking, after-sales service, and re-order support for OEM clients.

08

Trusted Silicone Manufacturer – Why Choose Us

About Haotian

Dongguan Haotian silicone technology Co., Ltd. was founded in 2009, specialize in providing customized solutions for multi-color and complex silicone products.After several years of continuous efforts and development, we have set up a complete manufacturing process from design, mold opening, vulcanization, printing, Surface treatment and packaging.We obtained the invention patent of silicone multi color integratedmolding process, as well as avariety of utility model patents and appearance patents. At the same time, we getthe certifications of ISO9001, IS014001, SEDEX, BSCI, etc. And also passed the factory audit byDisney, universal, IPS,etc. Now, we have established long- term cooperative relations with Disney,Universal Studios, B.Duck,P&G, LINE, HUAWEI, MINISO, and other famous brands and IP.

Disney FAMA Certified Factory

Certified by Disney and Universal Studios, with over 10 years of stable cooperation with leading international brands.

One-Stop OEM/ODM Service

From concept design to tooling, mass production, and packaging, we provide complete OEM/ODM solutions tailored to your brand needs.

In-House Design & Tooling Capability

Our professional team provides in-house design and tooling, enabling fast prototyping and customized solutions tailored to your product requirements.

Flexible MOQ for Wholesalers & Retailers

We offer flexible minimum order quantities to support both large-scale wholesalers and small retailers, making it easier to start and scale your business.

Professional Team for End-to-End Service

Our experienced professionals provide dedicated support from initial consultation to after-sales service, ensuring a smooth and worry-free cooperation.

FAQ

Yes, we specialize in OEM and ODM production. You can customize the bottle design, size, color, logo, packaging, and material to fit your brand or project requirements.

All our bottles are made from 100% food-grade platinum silicone and meet FDA, LFGB, and BPA-free standards, ensuring they are safe for food and beverage use.

Yes, we provide free standard samples or custom samples at a small cost, which will be refunded after the official order is confirmed.

For standard silicone bottles, production takes around 3–7 days. For new mold development or complex designs, it usually takes 7–10 days.

Our standard MOQ is 100–300 pieces per design, depending on your customization level. For new projects, we can offer flexible MOQs to support market testing.

Yes, we support silk screen printing, laser engraving, and embossed/debossed logos depending on your design and quantity.

We offer custom retail packaging, such as color boxes, hang tags, paper sleeves, or eco-friendly kraft boxes with your branding.

Yes. Our in-house design team provides 3D modeling, rendering, and mockup services to help visualize your final product before production.

We conduct 100% QC inspection at every stage — from raw material to final packaging — including leak tests, durability checks, and visual inspections.

We accept T/T, PayPal, and Alibaba Trade Assurance. Shipping can be arranged by sea, air, or express (DHL, FedEx, UPS) depending on your needs.

Let’s bring your brand ideas to life with premium, sustainable silicone bottle solutions.