Custom Silicone Sleeves – Protective, Durable & Brand-Ready

Durable, food-grade silicone sleeves customized for bottles, cups, electronics, and more.

Why Choose Our Custom Silicone Sleeves

Full Customization for Your Brand

Full Customization for Your Brand

Food-Grade & Certified Quality

Food-Grade & Certified Quality

OEM & ODM Manufacturing

OEM & ODM Manufacturing

Flexible MOQ & Bulk Supply

Flexible MOQ & Bulk Supply

Efficient Production & Fast Delivery

Efficient Production & Fast Delivery

Versatile Applications & Market Demand

Versatile Applications & Market Demand

Explore Our Silicone Sleeve Products

Discover a wide range of silicone sleeves designed for bottles, cups, glassware, electronics, and industrial tools. All products are made from food-grade materials and can be customized in size, shape, and color to perfectly match your brand’s needs.

Fully Customizable Silicone Sleeves to Match Your Needs

- Material

- Size & Shape

- Color

- Surface Texture

- Thickness

- Printing & Branding

- Label and package

Material

Our expert engineers will recommend the most suitable raw materials based on your requirements (e.g., liquid silicone rubber or solid silicone, tensile strength, tear strength, etc.), as well as different standards such as FDA, LFGB, or medical grade, and even specific material brands. If needed, antimicrobial agents can also be added to the raw materials to help the product meet sterility standards.

The custom silicone sleeves can be designed in sizes ranging from small bottle grips to large protective sleeves for containers and electronic devices, with thickness options from 0.5 mm to 5 mm. You can fully customize the size, shape, and color of the sleeves, making them perfect for water bottles, coffee cups, glass jars, electronics, medical tools, and industrial equipment.

If you prefer to use our existing sizes, we can print your logo and pattern on them. Below is a reference list of silicone sleeves in standard round, square, and other shapes designed for common applications.

Our silicone sleeves can be customized in any Pantone shade to align perfectly with your brand or product design. From subtle neutrals to bold and eye-catching colors, we provide full flexibility.

Color customization helps highlight your brand identity. Whether for promotional bottles, coffee cups, electronics, or retail packaging, your custom-colored sleeves make your products stand out.

Our custom silicone sleeves can be produced with different surface textures to combine style and functionality. From smooth matte finishes for a modern look, to glossy surfaces that highlight vibrant colors, and textured patterns such as ridges, dots, or embossing for enhanced grip and anti-slip performance. These textures not only improve the hand feel but also add durability by resisting scratches and wear. Whether you need a soft-touch finish for comfort, or a rugged design for extra protection, we can customize the surface texture to perfectly fit your product and brand.

Our custom silicone sleeves can be manufactured in a wide range of thickness options, typically from 0.5 mm to 5 mm, depending on the application. Thinner sleeves provide a lightweight, flexible fit ideal for cups, bottles, and everyday items, while thicker sleeves offer stronger cushioning and protection for electronics, glassware, and industrial equipment. By customizing the thickness, you can achieve the perfect balance between comfort, durability, and functionality, ensuring the sleeve meets both protective and branding needs.

You can customize the logo and pattern on silicone sleeves using the following methods:

Laser Engraving: Requires opening a jig for printing, with a cost of around USD 100 per jig. Suitable for simple logos or text, offering clear and long-lasting marking on silicone sleeves.

Silk Screen Printing: Best for basic patterns and solid colors. Provides durable, fade-resistant printing that is food-grade safe and dishwasher-friendly. Jig cost is around USD 100 per color.

Heat Transfer Printing & Water Transfer Printing: Ideal for complex designs, multi-color logos, or gradient effects. Printed transfer paper is required, with costs ranging from USD 299–599 depending on size and pattern.

In-Mold Decoration: Offers premium quality results with gradient effects and complex artwork. Extremely durable and high-end finish. Printed in-mold decoration paper is required, with costs starting at around USD 1,599.

Digital Printing: No jig or transfer paper needed. While the colors may not be as sharp as other methods, it is a cost-effective solution for small batch customization of silicone sleeves.

HAOTIAN provides customized packaging solutions (Kraft wrap, custom sleeves, boxes, OPP bags) for branded silicone mats. We offer one-stop services, assisting customers with packaging design, development, assembly, and inspection (including branding, UPC labels, and barcode labels), ensuring both market-ready product presentation and safe transportation.

Our dedicated packaging team is committed to guaranteeing that every finished product reaches end sellers with the highest quality and reliability.

Our custom silicone sleeves are made from high-quality, food-grade silicone that is 100% BPA-free, eco-friendly, and durable. They are designed to provide reliable protection for bottles, cups, glassware, electronics, and other items while adding comfort and style.

These sleeves are heat-resistant from -40℃ to 230℃, offering excellent insulation, anti-slip grip, and impact protection. Easy to clean, washable, and reusable, they are a sustainable alternative to disposable grips and protective wraps.

All silicone sleeves are certified to pass FDA, LFGB, and REACH standards, ensuring safe use in food-contact applications. They are dishwasher-safe and long-lasting, making them ideal for both daily use and custom branding projects.

Custom Silicone Sleeve Case Studies

Our Custom Silicone Sleeve Production Process

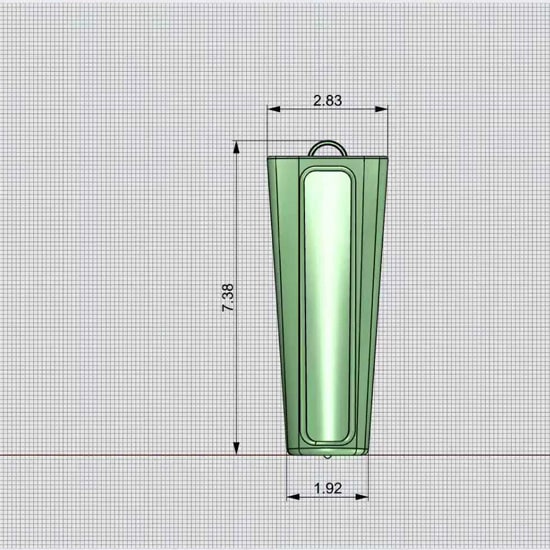

Design & Concept Confirmation

We start every project with a clear understanding of our client’s needs. Our design team works closely with you to finalize the size, shape, color, and functionality of your silicone sleeve. To make sure everything is accurate, we provide detailed 2D and 3D drawings for your approval before moving forward.

01

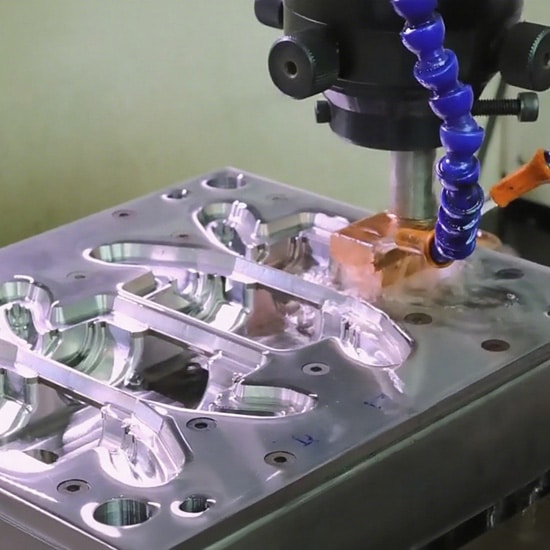

Mold Development

Once the design is approved, our in-house tooling team creates high-precision molds. These molds are the foundation for consistent, large-scale production. We ensure durability and accuracy so that every Sleeve produced matches the original design perfectly.

02

Raw Material Selection

We carefully select 100% food-grade silicone materials that are FDA and LFGB certified. According to your customization needs, we can add pigments for color matching or reinforcements for enhanced performance, ensuring both safety and aesthetics.

03

Molding & Shaping

The raw silicone is placed into the mold and shaped through high-temperature compression molding. This process gives the Sleeve its form and structure. At this stage, we can also add textures, embossed logos, or measurement markings for added functionality and branding.

04

Surface Finishing

After molding, each piece undergoes trimming to remove excess edges and polishing to achieve a smooth, non-stick surface. For branded orders, we carry out logo printing or color matching to meet your marketing and retail needs.

05

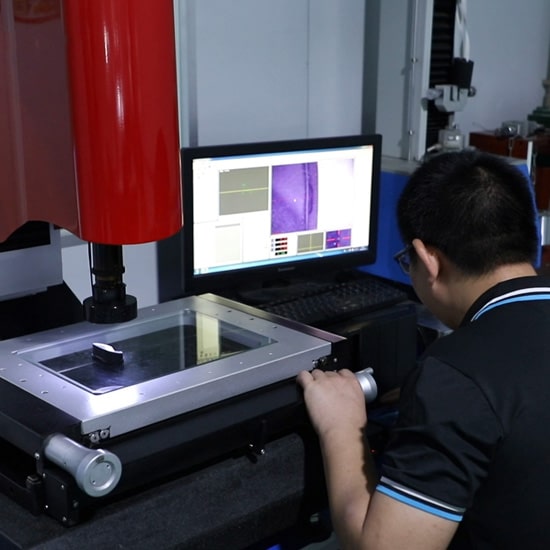

Quality Control & Testing

Every batch is inspected with strict quality standards. We test for accurate dimensions, hardness, elasticity, and heat resistance, as well as food safety compliance. Only products that pass all inspections move on to packaging.

06

Packaging & Branding

We offer flexible packaging options such as logo-printed polybags, color boxes, or retail-ready packaging. Each package is designed to keep your silicone mats moisture-proof, secure, and presentation-ready for your customers.

07

Delivery & After-Sales Support

Finally, we arrange reliable logistics to deliver your order on time, whether it’s bulk shipment or express service. Our professional team also provides after-sales support to help you with repeat orders or customized requests in the future.

08

Trusted Silicone Manufacturer – Why Choose Us

About Haotian

Dongguan Haotian silicone technology Co., Ltd. was founded in 2009, specialize in providing customized solutions for multi-color and complex silicone products.After several years of continuous efforts and development, we have set up a complete manufacturing process from design, mold opening, vulcanization, printing, Surface treatment and packaging.We obtained the invention patent of silicone multi color integratedmolding process, as well as avariety of utility model patents and appearance patents. At the same time, we getthe certifications of ISO9001, IS014001, SEDEX, BSCI, etc. And also passed the factory audit byDisney, universal, IPS,etc. Now, we have established long- term cooperative relations with Disney,Universal Studios, B.Duck,P&G, LINE, HUAWEI, MINISO, and other famous brands and IP.

Disney FAMA Certified Factory

Certified by Disney and Universal Studios, with over 10 years of stable cooperation with leading international brands.

One-Stop OEM/ODM Service

From concept design to tooling, mass production, and packaging, we provide complete OEM/ODM solutions tailored to your brand needs.

In-House Design & Tooling Capability

Our professional team provides in-house design and tooling, enabling fast prototyping and customized solutions tailored to your product requirements.

Flexible MOQ for Wholesalers & Retailers

We offer flexible minimum order quantities to support both large-scale wholesalers and small retailers, making it easier to start and scale your business.

Professional Team for End-to-End Service

Our experienced professionals provide dedicated support from initial consultation to after-sales service, ensuring a smooth and worry-free cooperation.

FAQ

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.