Introduction: From Concept to Creation

The entire range of silicone products that you see every day, like a custom silicone phone case, a multi-color wrist band or a specialized rubber gasket, begins as a simple concept but it requires a custom silicone manufacturing process just to get it. As the employee of Dongguan Haotian Silicone Technology Co., Ltd., the company established in 2015 and specializing in the customization of the multi-color and complex silicone products, I have managed hundreds of projects through sketches until the final delivery to the world market. With the in-house design and packaging, we are very precise and quality assured based on our invention patent of silicone multi-color integrated molding and certifications of ISO9001, ISO14001, SEDEX, and BSCI.

The buyers, designers as well as OEM clients need to know the entire silicone production process since it will demystify the way we achieve consistency, durability, and customization. Simply put the voyage consists of major steps: concept design and engineering, mold design and tooling, material selection and mixing, molding and vulcanization, surface treatment and printing, quality control and testing, assembly and packaging as well as the delivery. The process is a high-volume production method that reduces failure modes by creating silicone products within a step-by-step process that is highly efficient, which optimizes the high-volume OEM silicone products. We shall begin, and we are going to do it in big chunks one at a time.

Section 1: Step 1 — Product Design and Engineering

Thoughtful design and engineering is the basis of any successful custom silicone product, whereby the idea is paraphrased into a viable blueprint. At Haotian silicone, the client works closely with our team when it comes to initiating projects. We begin by looking at concept drawings or specifications or even rough sketches then proceed to 3D silicone modeling with high-end software, such as SolidWorks or AutoCAD, to see the final object.

The size of the product, its shape, and wall thickness, its flexibility, and purpose are some of the considerations that need to be provided, whether it is a custom silicone bottle that needs to be resistant to hot liquids or a rubber gasket that needs to be provided with sure tolerances to seal. We do consider end-use conditions, such as heat or chemical exposure, or UV, to make the design both moldable and functional. In the case of sophisticated products, we 3D print a prototype of the parts in silicone or use small-run prototyping, which enables clients to test-fit and feel the product before deciding to make it in large quantities.

This phase in designing a silicone product is important as the cost later revision is avoided. We have found it is more time- and resource-saving in our world to repeat such a step, perhaps by adjusting the radii to a more favorable flow during molding, and particularly it is true of OEM silicone products, where branding elements such as logos need to fit together smoothly.

Section 2: Step 2 — Mold Design and Tooling

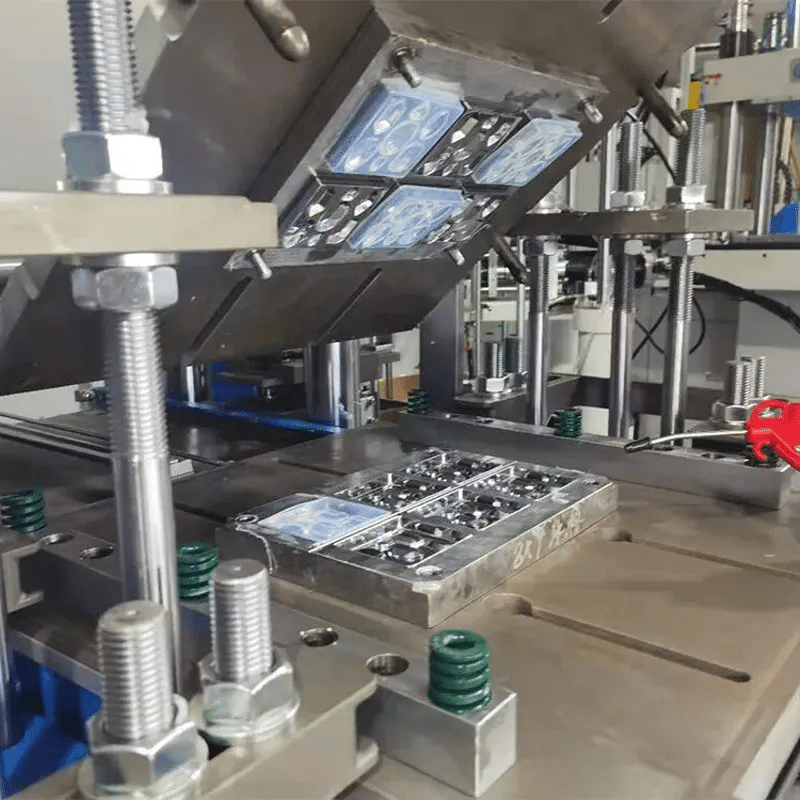

After the design has been accepted we advance on to mold design and tooling which is the backbone of precision in silicone manufacturing. The accuracy of the product depends on molds and hence we spend a lot of money in this process by using CNC machining or electrical discharge machining (EDM) to produce good quality steel or aluminum tool.

Such parameters as parting lines (mold halves parting) and venting arrangements (to remove air) and temperature control pathways are carefully designed to prevent such defects as bubbles or unsatisfactory fills. The kind of mold varies according to the project: Compression molds are excellent with thicker, more straightforward components such as custom rubber gaskets; LSR injection molds are well suited with high-precision, high-volume parts such as phone cases; transfer molds are able to cope with complicated geometries with built-in components.

Molds are durable and reusable with our in-house tooling capacity; which has been developed over the years since being audited by Disney and Universal so they last their millions of cycles. This is the step in which our invention patent of multi-color integrated molding excels, and we will be able to make tools that result in the development of colorful and smooth designs without any secondary operations.

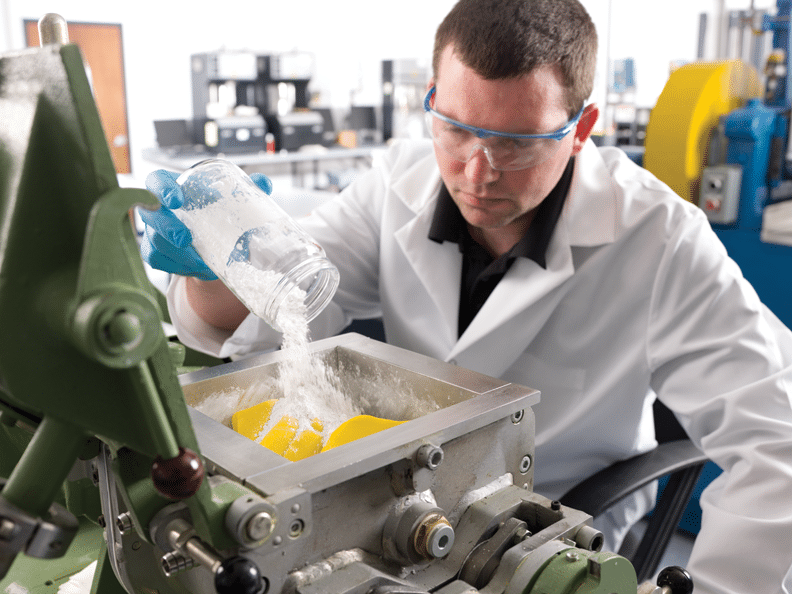

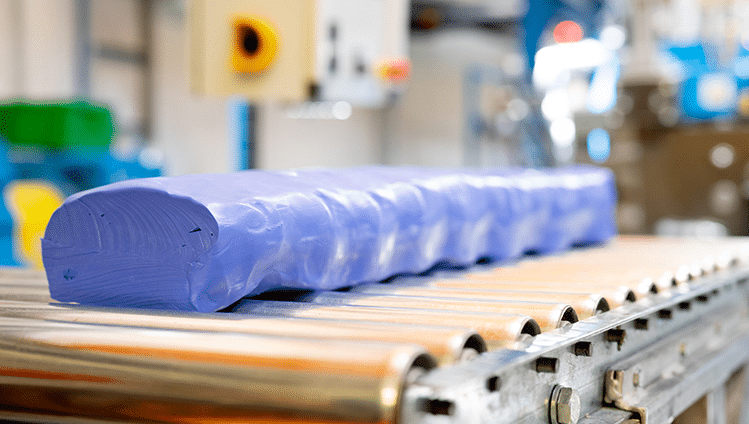

Section 3: Step 3 — Material Selection and Mixing

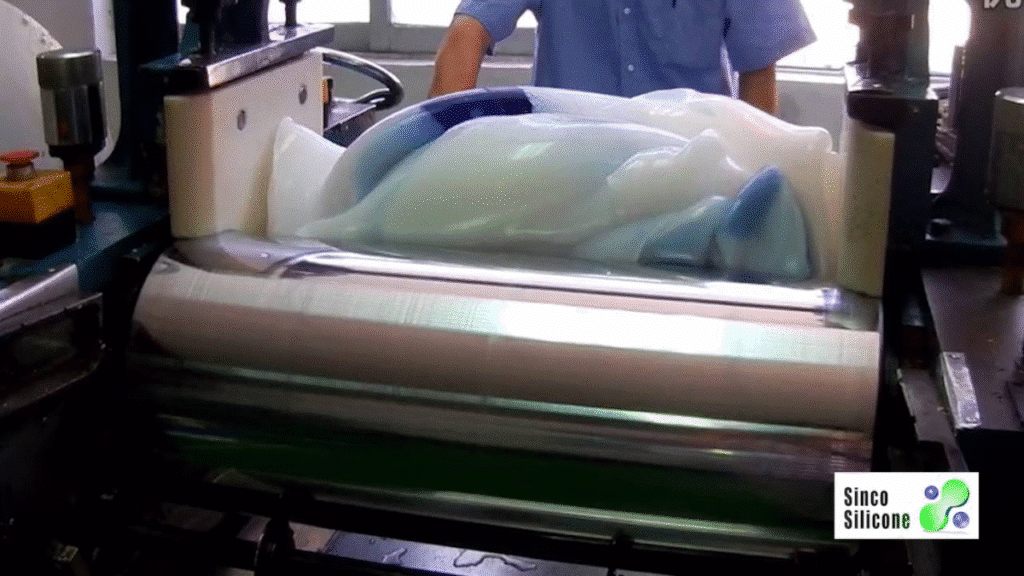

The science comes into contact with customization at the material selection where the proper grade of silicone rubber is used to make sure that the product works as well as it can. We have many types: Liquid silicone rubber (LSR) when intricacy of detail is required, High Consistency Rubber (HCR) when strength is needed, fluorosilicone when resistance to chemicals is necessary, and food grade silicone when contact with humans is needed as is the case with baby products.

Such properties as hardness (range 20A soft to 80A firm in Shore A durometer), tempering range (-60degC to +230degC), and suitability with FDA or LFGB are considered according to the needs of customers. In the case of branded products, multi-color silicone mixing is a process of blending pigments with pinpoint accuracy of color matching Pantone, and without bleeding.

We combine materials in controlled circumstances in our SEDEX-certified plant, ensuring no contamination takes place, with any additives being added and this is to give the product UV stability or antimicrobial properties based on need. This process of selecting silicone material is a crucial requirement that the OEM silicone factory projects cannot afford a compromise on because uniformity among batches is a prerequisite.

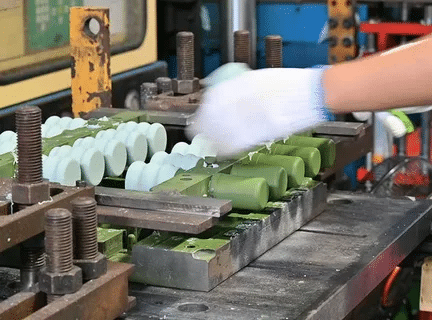

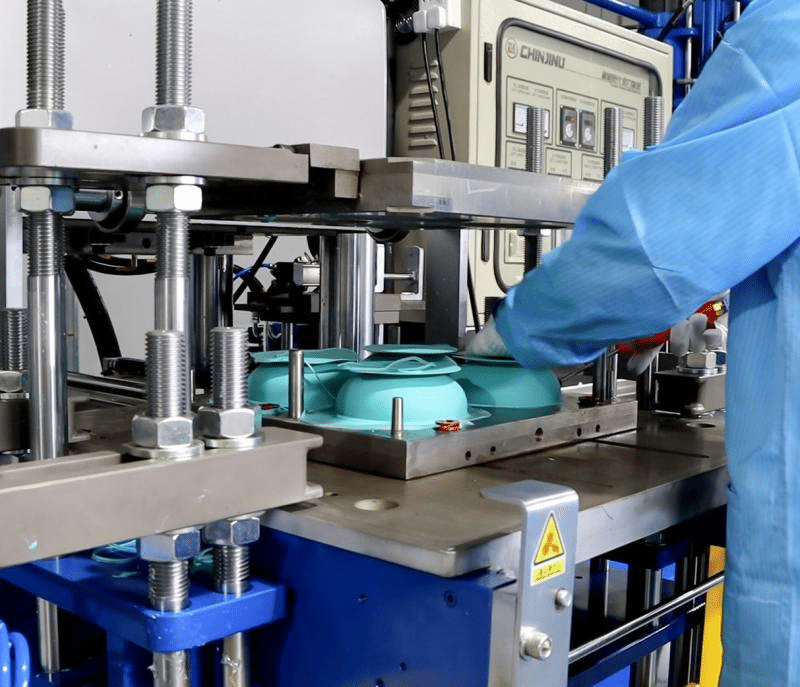

Section 4: Step 4 — Molding and Vulcanization Process

Molds are prepared, materials are mixed and the core silicone molding process commences where unrefined silicone is converted to molded products under heat and pressure. Compression molding is done by loading the pre-weighted silicone in the molding cavity, closing the mold and heating it (approximately 150-200degC) to vulcanize- the chemical bonding that imparts elasticity and strength to silicone.

To achieve more accuracy, we resort to liquid injection molding (LIM) with LSR where the liquid is forced through a high pressure injection into heated molds to cure within a few hours, which is best used in complex shapes such as a custom silicone phone case. Transfer molding is appropriate when inserts are used, material is forced through the sprues into the mold.

The magic moment is the vulcanization of silicone: The material becomes solid (under regulated heat and time, usually 5-10 minutes per cycle) and acquires such final properties as tear resistance and flexibility. We are ISO14001 compliant which means that we have an energy efficient process and waste will be minimal in this injection molding silicone process.

Section 5: Step 5 — Surface Treatment and Printing

After molding, the surfaces and printing are done which improve the functionality and attractiveness of these parts to create products ready to go to the market. We provide matte or smooth surfaces through etching using plasma or other chemicals enhancing either grip or smoothness to products such as personalised silicone mats.

On silkscreen work or pad printing, silver and dyeable inks used are long-lasting, non-toxic and are resistant to washing off. Serial numbers can be permanently marked on the rubber gasket using laser engraving and optional features can be added through finishes such as anti-static or hydrophobic.

This is the silicone surface treatment step and where our multi-color techniques shine through giving us vibrant color designs that fade away. In case of food-grade products, there is no contamination of any processes.

Section 6: Step 6 — Quality Control and Testing

The quality control is something that can not be compromised and it is integrated throughout the process, but here it is finished with strict checks. We test dimensional accuracy on calipers and the CMM machines, and tolerances can be as small as +-0.05mm.

Tensile strength, hardness, and elongation are measured according to the ASTM standards, and the color consistency is measured using the spectrophotometers. When the test is conducted on food-grade or children foods we perform the odor, migration and safety evaluation according to the FDA, LFGB standards.

We have silicone test requirements with both ISO9001 and BSCI which involve defects inspection and functional tests such as heat cycling. This silicone quality control would guarantee that each lot is manufactured to client specifications, which would instill confidence in our OEM silicone manufacture.

Section 7: Step 7 — Assembly, Packaging, and Delivery

Finally, assembly attaches components such as adding metal inserts to silicone bottles and lastly, inspection. Packaging is tailored: greener packaging such as recyclable boxes that can be branded, which protects goods on their way.

The logistics include silicone product packaging that is ready to be exported, and tracking of global deliveries. The collaboration with such brands as LINE and MINISO proves us as stable silicone delivery, both within Dongguan and the global customers.

Section 8: Step 8 — Continuous Improvement and Innovation

In addition to delivery, the novel silicone production requires constant improvement. We invest in automation at Haotian Silicone to have faster cycles and environmentally friendly mechanisms within the ISO14001.

The trends such as smart wearables are pushed by our multi-color silicone technology patent, with an R&D of bio-based silicones at 2026 sustainability. Such a promise to automation in silicone manufacturing and quality makes us deliver better customer value in OEM/ODM solutions and make customer visions a reality with experience and honesty.