Introduction: Precision Defines Quality

Precision mold design is the key to quality and consistency in silicone industry where a single one millimeter could spell out the difference between a perfect product and a rejected batch. Being the employee of Dongguang Haotian Silicone Technology Co., Ltd., a company that was started in 2015 and focuses on the creation of individualized solutions to multi-color and complex silicone products, I have managed millions of projects in which complex ideas were transformed into solid and well-focused products due to the presence of high-precision molds in the mold design. Fine tolerances: +-0.02 to 0.05 mm This is what makes our products, such as complex phone cases, medical seals, multi-color wristbands, etc., work as desired, with no defects or variations.

This accuracy is essential due to the fact that complex silicone designs may entail thin walls, undercuts or integrated colors where any deviation can influence fit, sealing or appearance. In this paper, I will discuss our strategy at Haotian Silicone based on our patent of silicone multi-color integrated molding process and also our ISO9001, ISO14001, BSCI, SEDEX certifications along with Disney, Universal, and IPS factory audits. We will discuss what is meant by precision, our cutting-edge engineering, machining, modifications to LSR and HCR, color systems, quality mechanisms, continuous enhancements, real practices, and our dedication to fine silicone manufacturing.

Section 1: Why Precision Matters in Silicone Manufacturing

After all, a manufacturing process requires precision in silicone, which is not only a technical necessity but the difference between a good product and a failure. Minor variations in the size of molds may cause problems including unevenness in wall thickness, lack of alignment in colors or defective sealing particularly in high standard industries. As an example, in medical equipment, a mold tolerance error may cause sterility or fit or, in electronics, lead to leaks or electrical shorts.

The precision is especially crucial in the case of high complexity of design of the molds, where micro-channels and multi-material integrations are typical. Haotian Silicone has silicone mold tolerance level of +-0.02 mm in critical parts and this is consistent across the batches. This is necessary to consumer products such as custom silicone phone cases where beauty and functionality form brand confidence. In our case, precision enables waste reduction, reduced rework and increased customer satisfaction which is a non-negotiable in silicone production excellence.

Section 2: Advanced Mold Design and Engineering at Haotian Silicone

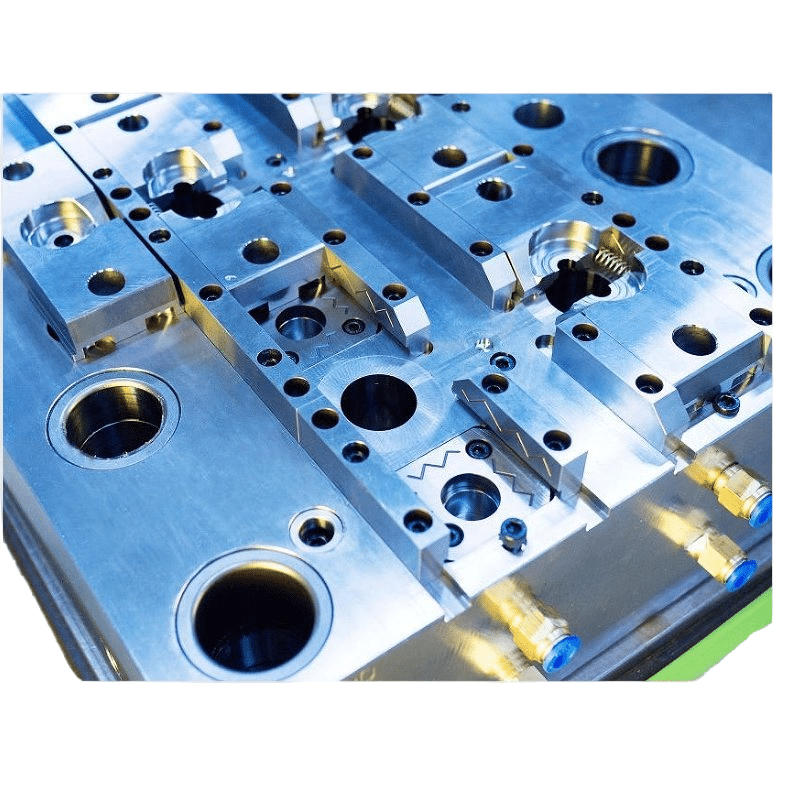

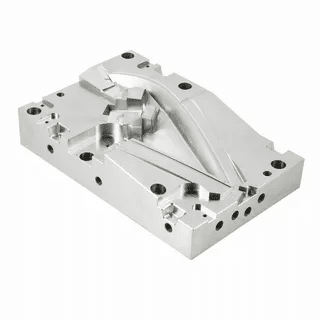

We start with ultra-modern mold design and engineering, in which precision is incorporated at the very outset. Our group of skilled engineers reviews the client CAD files, and the files are optimized to be manufacturable, without altering the original vision. Our detailed 3D models are designed using programs such as SolidWorks and AutoCAD and which are used to simulate 3D processes such as mold flow, cooling and ejection; and anticipate possible problems such as warping or air traps.

One of the tools that come to play here is that of the finite element analysis (FEA) where we can virtually stress-test our designs and optimise our tolerances, prior to physical tooling. In complex silicone designs molds, consultative reviews with clients are made, whereby feedback is taken, and all the details such as parting lines, vents positions among others are perfect. This stage of the silicone mold design is aided by our R&D investments; it takes the experience of our engineering team and allows them to create the silicone mold with the precision of the microns, which preconditions the error-free production.

Section 3: Precision Machining and Tooling Process

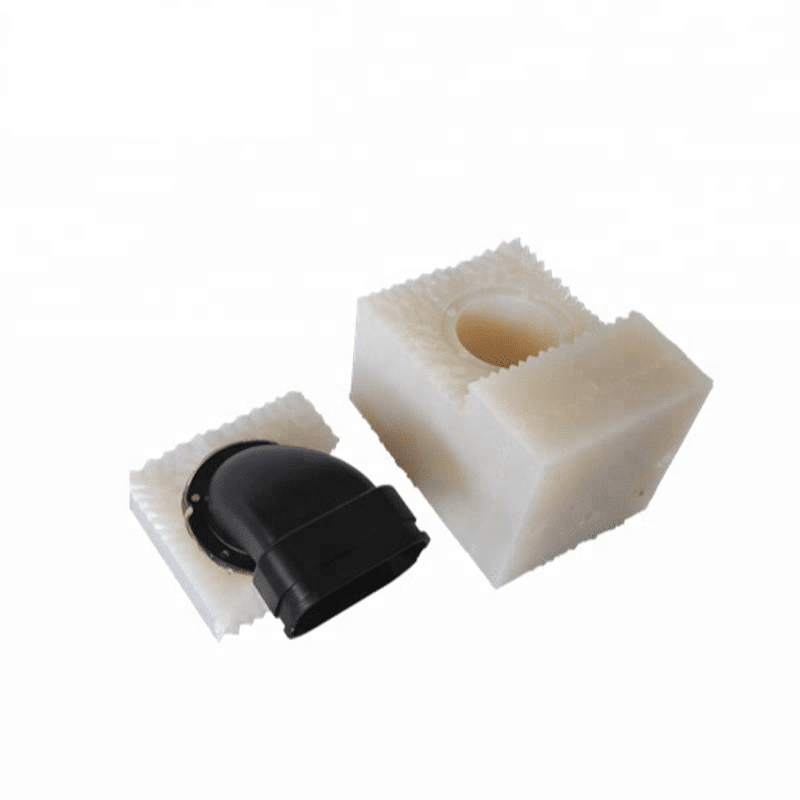

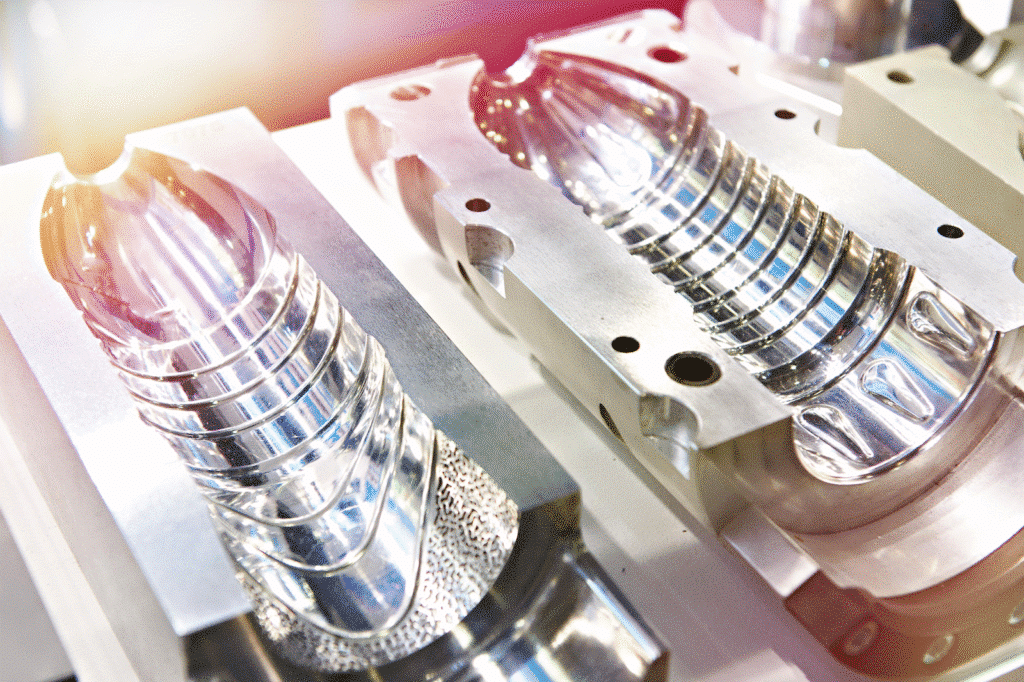

Precision machining is a process that makes the designs come true and at Haotian Silicone, we have the latest CNC machining and EDM (Electrical Discharge Machining) through which we make the molds designed to be very precise. Complicated cavities can be milled at high speed in CNC centers to surface finishes as smooth as Ra 0.2 mm, which is necessary with mirror-like silicone parts.

EDM mold processing is most effective when the feature to be processed is hard-to-reach or made of hard materials, and electrical sparks are used in order to cut metal without any mechanical stress. Depending on the complexity, we use high grade tool steel which is durable during high volume production or aluminum which is faster in prototyping. Thermal expansion that would cause tolerances to be skewed is inhibited by environmental controls in our tool room such as regulation of temperatures to +-1degC.

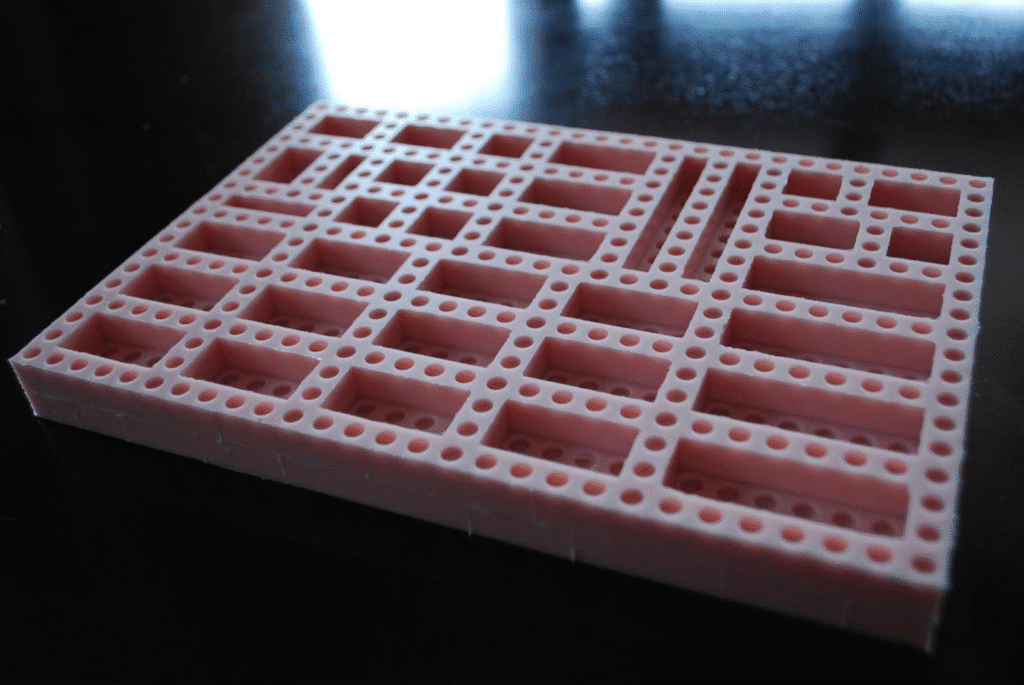

Multi-cavity silicone molds are planned using layouts that promote consistent fill and cooling, which facilitate consistent output. This method of CNC machining silicone molds in combination with mirror polishing reduces flaws such as flash or sink marks, thus allowing the creation of highly accurate shapes in molds where even the toughest projects are concerned.

Section 4: The Role of LSR and HCR in Precision Molding

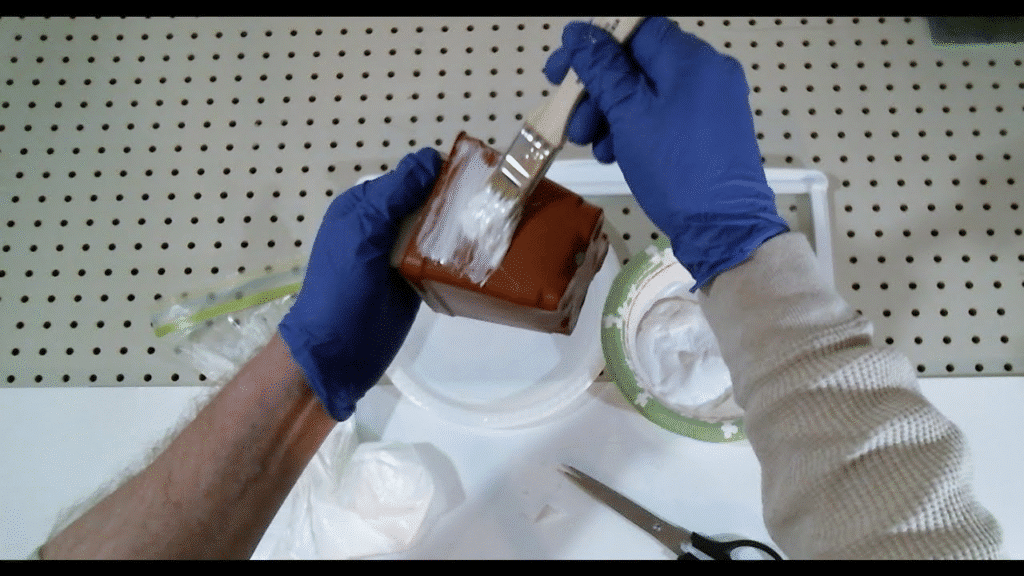

It is essential to modify molds to the types of the materials, and we are experts in LSR (Liquid Silicone Rubber) and HCR (High Consistency Rubber) to fit some different requirements. LSR precision molds will need maximum precision in the alignment and temperature control, because the low-viscosity material flows into fine details. Our LSR injection molds include balanced gating systems to eliminate imbalances in flow, and have high-tolerance silicone mold engineering of such parts as thin-walled medical tubing.

HCR mold manufacturing which is usually done through compression or transfer is more appropriate to thicker or more durable parts, where the mold is designed to achieve uniform distribution of its pressure so as to keep the part in the desired shape. We trade off both LSR (intricate multi-shot integrations) and HCR (robust high-stress applications) in complex designs. Our technologies are patented which allows our processes to guarantee that silicone injection mold can be accurate and tolerances can be maintained even after curing because of our processes.

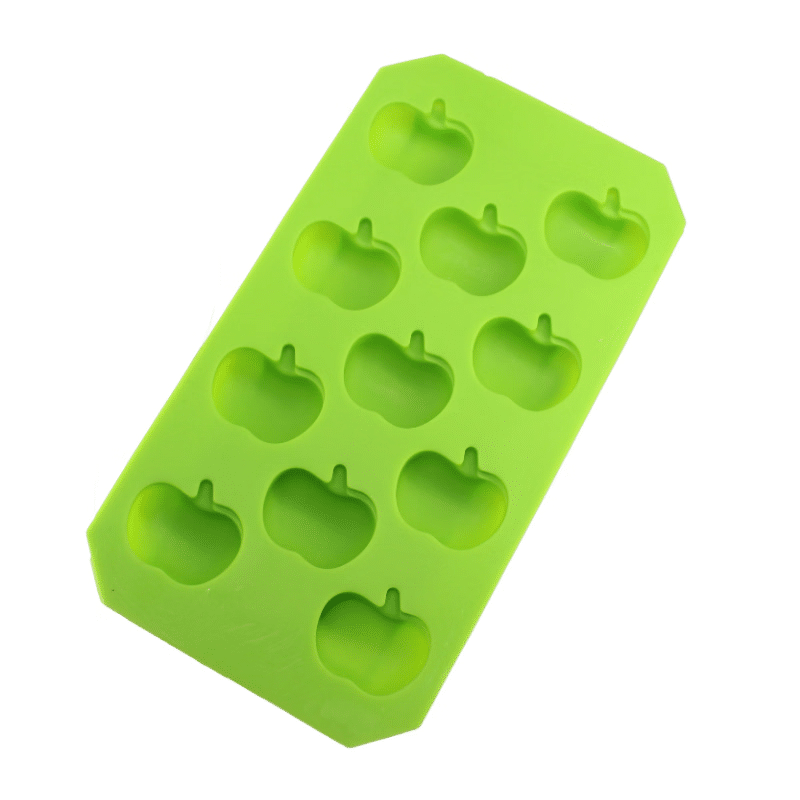

Section 5: Achieving Perfection in Multi-Color and Complex Geometry Designs

In the case of multi-color silicone molds, our multi-color integrated molding process provides a means of accurately separating colors without bleeding by means of special gating and sequential injection. The color-built molding accuracy allows multicolored, textured patterns on items such as a wristband or keypad.

Complex silicone design molds can deal with geometries that contain undercuts or thin walls with sophisticated features such as slide actions or collapsible cores. Micro-details are added by high-speed milling and laser engraving and flow balancing prevents the defects in 3D-curved surfaces. The design of complex molds is such that the various layers are perfectly aligned giving products of the best specifications to various industries such as consumer electronics.

Section 6: Quality Inspection and Validation Systems

Quality is not an add-on but a part and parcel. Coordinate-measuring machine (CMM) are used to determine dimensional accuracy, and surface defects are scanned using optical equipment, whereas the integrity of the material is tested by hardness and tensile tests.

In multi-color components we make checks on alignment and color fidelity with spectrophotometers. Our silicone mold testing involves trial tests to ensure that performance is attained in the real world. The ISO9001, BSCI, SEDEX, and Disney audits will help in making sure that our CMM measurement silicone processes are up to global standards that will create confidence in all our molds.

Section 7: Continuous Improvement and Technological Upgrades

At Haotian Silicone, precision is also driven by continuous improvement. R&D is an investment that we make to upgrade CNC centers with automation that improves quicker and more precise tooling. Our sophisticated mold manufacturing technologies are improved with the help of the collaboration with material suppliers and engineering universities.

Innovation is encouraged by our Four Hearts philosophy, Progressive, Tolerant, Awe, and Grateful, such as the perfecting of EDM processes to meet the details. This innovation of silicone factory makes us remain in the forefront of precision silicone technology which is able to adapt to the requirements of the clients with narrower tolerances.

Section 8: Real-World Examples of High-Precision Projects

We specialize in actual projects, such as multi-color silicone phone covers with complex logos, where molds are used to provide smooth color changes and +-0.03 mm tolerances to ensure a perfect fit. Our custom silicone molds China are used in medical-grade seals and are leak-proof guaranteed to save lives in our devices.

In electronics, we prepare button molds with high-accuracy technology in micro-thickness which avoids failure during high-use situations. Our OEM silicone components to consumer products engineering, tooling and inspection synergy is exhibited in these silicone precision projects.

Section 9: Expert Conclusion — Precision as a Promise

Precision silicone is our promise at Haotian Silicone, and we deliver it through the use of pure craftsmanship, high-tech tools and utmost dedication. As the high-accuracy mold technology is being innovated we are anticipating to stretch ourselves in complicated designs as each and every product will over-deliver.