Amidst tremendous leaps and bounds in the medical field, very few materials have gained as much recognition as that of silicone. The biocompatibility and the ability of this material to fit into various chemical environments has made this compound to find its way in a variety of medical applications from mere tubing to implantable devices. But what exactly is medical silicone and why is it indispensable in the contemporary world of medicine?

What is Medical Silicone?

It is a synthetic polymer that is formed by silicon, oxygen and carbon filled with hydrogen; it is a highly flexible material that is resilient and is used in the production of medical equipment. Different from other forms of silicone that can be accessed in the market, medical grade silicone is thoroughly purified to eliminate finding of traces of impurities and through a series of test to ensure that it fits the required standards for use in the the medical device manufacturing field.

Properties of Medical grade Silicones

1. Biocompatibility

The greatest feature that must be highlighted regarding medical silicone is its biocompatibility. In other words, it can engage human enzymes or tissues and produce no negative effects. This property makes it appropriate for use in implants, catheters, and any item that contacts the human body directly.

2. Flexibility and Durability

Medical silicone has excellent flexibility and abrasion and as such it can be in a variety of formats. Silicone can be a very soft, pliable sheet that conforms to the necessary shape or a strong molded part that can stand up to the tough conditions of the medical world without deforming and becoming ineffective.

3. Temperature Resistance

Medical silicone can also be used in areas of very heat resistance at low or very high temperatures since it has the ability to handle both. This property is of much significance in uses like sterilization, in which materials have to withstand high temperature without degrading.

4. Chemical Resistance

Medical silicone also has to have a chemical resistance since it is used in contact with human body fluids. According to the details, it does not interact with body fluids, drugs and fluids, and cleaning agents, which means that the product still has a fairly good efficacy despite its age.

What Is the Difference Between Silicon and Silicone?

Thus, silicon and silicone are slightly similar in their titles but are very dissimilar compounds with different capabilities. Silicon is a crustal material in the earth, with the symbol Si on the periodical table of elements. It is a very rigid and fragile crystalline at low temperatures and is an abundant element in the Earth’s crust, mainly in form of sand, clay and many minerals. Silicon is extensively used in electronics sector because of its high semiconducting nature and it is backbone of computer chips, transistors, etc.

Whereas silicone on the other hand is described as a synthetic polymer composed of silicon, oxygen, carbon and hydrogen. Si is an elemental compound while silicone is a synthetic polymer often found as an oil or gel or substance similar to rubber. Silicone enjoys diverse application, it can be in articles of medical use, kitchen use, sealants, and even lubricating injection molding. Silicone is also favorable for its flexibility in use, its ability to work well in wet environments and its traffic notes for room temperature.

The major distinction made between the terms silicon and silicone, is in the fact that they are different substances with different applications. Hence silicon as an element is mostly used as such or in combination with with other elements for making electronic components and metallurgical uses. Silicone is a compound used as the main material or input in any industry that needs a tough, elastic, and medical grade product. And while silicon is the key element in electronics, silicone is present in everything starting from household items, medical equipment, and ending with industrial uses liquid injection molding.

Summing up, silicon is a natural element which occupies the great demand on electronics industry, and silicone is the synthetic polymer using in many types of spare parts of consumer and industrial goods. These variations in its molecular form, characteristics mechanical properties and applications provide the criterion of differentiation between silicon, which is a raw material on its elemental form, and silicone, which is an engineered material with multitudes of functions silicone rubbers.

How Is Silicone Made?

The process of making Silicone is quite a lengthy one which starts with silicon that can be obtained from silica which is the compound common in sand or quartz. The first process takes silica, which is put into a furnace with carbon to get metallurgical silicon. This silicon is then reacted with methyl chloride in the presence of a catalyst to form some compounds known as methylchlorosilanes. These are then distil with the most vital one being dimethyldichlorosilane as it acts as the guide or base for silicon.

Dimethyldichlorosilane first is hydrolyzed by means of joining it with water, at which the chlorine atoms are displaced by the hydroxil groups. This reaction leads into the formation of silanols and through further condensation of the latter, long chains of siloxanes is formed high consistency rubber. These siloxanes can be further polymerized to silicone oils, gels, or rubber as the end use application maybe required. More likely silanes, alcohols or other may be added to fine-tune the characteristic like more elasticity, greater hardness or heat useless, creating the multitude of silicone materials used in modern products food grade silicone.

What Is the Difference Between Silicone and Medical-Grade Silicone?

Even though a substance commonly may be both silicone rubber and a medical-grade silicone, the two are not completely alike as the latter is purer, comes with stricter quality control and mainly used in hospitals. Silicone can be described as a wide group of man-made plastics that is based on silicon, oxygen, carbon and hydrogen. Today it has found its application in different industries for different products such as sealants adhesives, lubricants, and household items because of its flexibility, water resistance, and other such features that it can also work in extreme temperatures. Silicone rubber is more general-purpose and was not reportedly subjected to the same levels of testing, let alone purification to become an actual medical grade product.

whereas medical grade silicone is a very purified form of silicone that is used for medical purposes only. This type of silicone is prepared to be specifically biocompatible, which means that it can be significantly in contact with the human tissues without creating distressing effects on the body. Medical grade silicone needs to fulfill certain specified guidelines, which includes the ones provided by the FDA or any other related department, to ensure that it is as pure as possible that would not hurt the human body especially where it will have a direct interaction with patient for long term use being in devices, implants, and the likes.

The only major distinction that can applied between conventional silicone, and medical-grade silicone is relative to their degree of purity as well as their safety. Thus, although non-medical grade silicone may include impurities like additives or contaminants which are in any case not damaging when applied in industrial or everyday uses, medical grade silicone is processed to eliminate any substance which may be undesirable or carcinogenic. Such a high purity is necessary, as the material is applied in sanitary items such as catheters, implants, and bandages, where contaminants can become a critical issue.

Therefore, it can be seen that silicone is a common material for use in many industrial applications as well as in common usage applications but the material is far from being pure and it is not subjected to high quality standards as it is the case with medical applications. Medical-grade silicone is a finer quality of silicone that can be used in health facilities because it has to meet set high standards to be used with or on people without side effects.

Applications of Medical Silicone in Healthcare

Based on the characteristics, medical silicone is widely used in various medical fields. In this section, let us look at some of the more typical uses of the technique.

1. Medical Implants

a. Breast Implants

Another familiar use is breast implants that are created from silicone. These implants are selected due their ability to give a natural look and feel, as well as being compatible and long term solutions.

b. Joint and Bone Implants

It is also incorporated into orthopedic implants, specifically those of the joint replacement type. It is very a versatile material and an intrinsically strong material, which makes is perfect for used in applications which require moving parts which are under pressure.

c. Cardiovascular Implants

The cardiovascular area for example employs liquid silicone in the fabrication of stents, heart valves and other implants which need to be left permanently within the human body without provoking any inflammation or deteriorating over time.

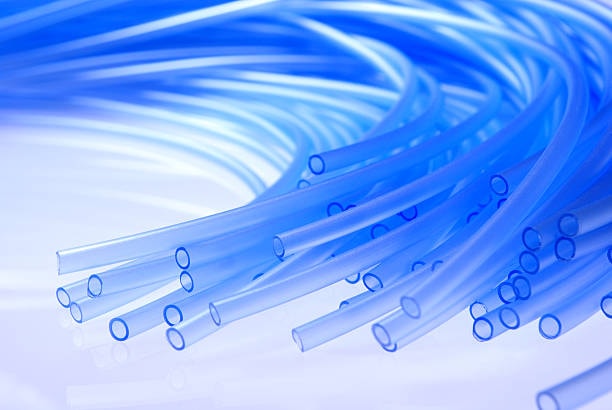

2. Medical Tubing and Catheters

a. Catheters

More specifically, silicone catheters are common since they are smooth, bendable, and irritate the patient’s skin less. They can be employed for either a short term or for a long term basis.

b. Drainage Tubes

The nature of drainage tubes to remain in the body for relatively long time and the fact that they remove fluids from the body, it has to be flexible and biocompatible which is provided by the medical silicone.

3. Wound Care

a. Silicone Gel Sheets

The silicone gel sheets are used in removal of scars and heal wounds. They aid in diminishing ruddiness, making each raised scar to be smooth, and even in making the skin to look better.

b. Dressings and Bandages

Another sort of merchandise is silicone dressings, which don’t stick to the wound tissue due to their non-stick feature. this property ensures that patients experience little pain or harm to the tissues especially during the dressing process.

4. Prosthetics

Prosthetic limbs and all devices of artificial body parts are made from Silicone. Due to its proclivity to mimic the smooth feel and elasticity of the skin it is a preferred material in construction of prosthetic limbs.

5. Drug Delivery Systems

a. Implantable Drug Delivery Devices

Due to the potentially long life of a silicone implant and its dual characteristics of chemical inertness and biocompatibility, it is well suited to the use in slow release, implantable drug delivery systems, used in releasing medication over time.

b. Transdermal Patches

Silicone is also employed in transdermal patches since it assists in controlling the amount of drug that diffuses through the skin.

6. Surgical Instruments and Tools

Medical silicone is widely applied in crafting of surgical accessories and devices where it is used to make handles, grips, seals etc. These are the non-slip texture and sterility of the surface in these applications.

How To Know If Something Is Pure Medical-Grade Silicone?

Besides, it can be said that the most essential procedure in defining whether it is made of the pure medical grade silicone is to look at the certificates of its compliance with the necessary standards and legal requirements. Medical grade silicone must also adhere to the regulation requirements for the use in medical applications, from the likes of U. S. Food and Drug Administration (FDA), the International Organization for Standardization (ISO) or other similar recognized institutions. Medical grade silicone products are usually labeled or certified to meet such standards as FDA or CE marks, or the international standards ISO 10993 for biocompatibility of medical devices.

The second sign to look for is manufacturer documents, which would prove that the medical-grade silicone is pure. This documentation should entail the description of the process of manufacturing, the type of material used as well as the measures taken in the testing of the product with consideration to its biologically compatibility and purity. Companies that produce medical-grade silicone often give their customer material safety data sheets (MSDS) or certificates of analysis (COA) that list the substances included in the silicone and guarantee that the material is in fact producing medical grade silicone.

Finally, one can look at the physical characteristics of the silicone and this is a little bit reliable depending on the result of the laboratory analysis. For instance, the material commonly used in medical products is known as Medical Grade Silicone, which is perfectly safe, and it does not emit any smell and nor does it release any unsafe substances into the surrounding environment or compromise its own structure when subjected to commonplace caucuses such as exposure to blood or sweat and other body fluids or when exposed to sterilization procedures. However, visual inspection is not enough to ascertain the purity of the item; thus, it is recommended to check certified records and trustworthy sellers to know whether the product is genuinely composed of pure medical grade materials or-grade silicone.

Why Silicone is More Eco-Friendly Than Plastic?

In comparison to plastic, silicone is usually regarded as more friendly to the environment mainly because of its ability to be recycled, as well as its long service time and relatively low environmental footprint all through its life cycle. Explaining the differences between plastic and silicone he pointed out that while plastic is another product of petroleum and is often used for things that do not have very long useful lives, silicone on the other hand, is made from silica sand. Silicone products are known to be long-lasting products, for in most cases they last far longer than other plastics products by probably a number of years. This durability ensures that silicone items are used for longer periods, therefore the rate of depletion of resources as well as the rate of production of waste is minimized.

The other huge benefit of silicone to plastic is that it has reliable temperature and chemical endurance, enabling it to be utilised in cycles without erosion and discharge of injurious products. He said plastic products, and particularly single-use categories, tend to deteriorate over time and relinquish microplastics and toxic additives into the environment. Whereas solid silicone rubber remains stable and does not degrade into dangerous micro-particles; therefore, it is safer to use in items that are ingested, come into contact with beverages or water, or those that have skin contact.

Another factor making silicone environmental friendly is recyclability. In contrast with other kinds of plastics, which can be problematic to recycle because of contamination or the presence of diverse types of polymers, the silicone material may be processed downcycling to such products as playground surfaces or industrial lubricants. While silicone recycling is not quite common compared to plastic recycling, the fact remains that silicone can be used, reused, and rerouted while maintaining its core attributes, which is a plus to this type of material.

Consequently, it could be evidently said that silicone is more environmentally friendly than plastic because of being long-lived, non-biodegradable, and having less toxic content than plastics. It leads to the least amount of waste being churned out after a while and is relatively safer to the environment and people. Even though it needs some amount of energy to produce, therefore not an essentially green product, it has the benefits of lasting longer than other plastics and can, therefore, be recycled for use in other products for a longer period as compared to traditional plastics.

Advantages of Using Medical Silicone

Nowadays, medical silicone is used on a large scale – and it is not without reason. The following outlines some of the main benefits that place it high on the list of preferred material in the healthcare industry.

1. Safety and Biocompatibility

Yet, silicone is chemically inactive and thus does not ignite any response with body tissues and fluids; this makes it to be used in many different medical uses. It’s for this safety profile that silicone is used most in the medical facilities and surgical procedures.

2. Versatility

Silicone’s versatility of being able to immediately conform to any shape or form within the field of medicine make it possible to create an extensive variety of products for medical use and its parts. Whether it is silicone molding a valve the size of a thumbnail or an implant for a human body, silicone can be made according to a specific requirement.

3. Sterilization Compatibility

The use of SIL itself makes the medical devices very easy to sterilize where some of the sterilization methods include; autoclave, gamma rays and Ethylene oxide gas. This also ensures that silicone devices should be free from any contamination and safe to be used in hospitals and health facilities.

4. Long-Term Durability

The material commonly used is medical silicone which is meant to have a very long life expectancy. It is also very strong and does not wear out, degrade through chemical action or heat, readymade for long term implants and instruments.

5. Comfort and Patient Compliance

The flexibility of silicone as a material makes medical devices made out of this material gentle on the patient’s body. This comfort enables the patient to be compliant especially when the device needs to be worn for a long time in the case of some chronic illnesses.

Challenges and Limitations of Medical Silicone

All in all, despite all the above listed benefits of medical silicone, it is not without its hurdles. It is important for healthcare providers as well as the patient’s to have such an understanding so that they can be in a better position to manage their health.

1. Cost

When using medical grade silicone especially in products with many parts or used as implants, the costs could be high. This cost can at times act as a discouragement to the use of this innovation thus limiting its diffusion.

2. Potential for Allergic Reactions

Normally, people do not show any signs of allergy to Silicone but there are numerous cases that reported allergies from this material. One can conclude that there is the necessity of proper testing and selecting the materials which are based on silicone before using the implants or other devices.

3. Limited Use in Load-Bearing Applications

Even, though liquid silicone rubber is tough and very pliable, it is not recommended for use where lifting loads is involved. In some situations, it is required to use other materials in construction to obtain sufficient strength and sturdiness.

The Future of Medical Silicone

It seems that the further use of medical silicone is planned, as the work is being carried out to broaden its usage even more.

1. Advancements in 3D Printing

Another characteristic of advancements in polymers is coming through with 3D printing with medical silicone is limiting the options for customized implants and devices. It makes it possible to implement individualized patient solutions to boost the efficiency of the therapy.

2. Integration with Smart Technology

Scientists are trying to find techniques to incorporate silicone with additional intelligence like sensors and electronic parts. This could also result into the creation of intelligent and what could be termed as self- regulating implants that are capable of detecting and adapting to the body’s condition in real-time.

3. Enhanced Biocompatibility

Recently, silicone continues to receive research attention regarding the decrease in skin sensitization reactions, need for better biocompatibility and its use in performance applications.

Conclusion

It is clear that the application of medical silicone has greatly changed many spheres of medicine offering patients safe, reliable, and long-lasting products all around the world. With the future hindsight in technology, it can be forecasted that the usages of medical silicone will carry on improving, providing more creative methods and equipment in the healthcare field. Although cost and some people’s allergic reactions to medical silicone can still be considered as drawbacks, its advantages are significantly greater in this case, and this material will remain one of the key in the further development of medicine.