Introduction: The Critical Role of Sealing in Automotive and Industrial Systems

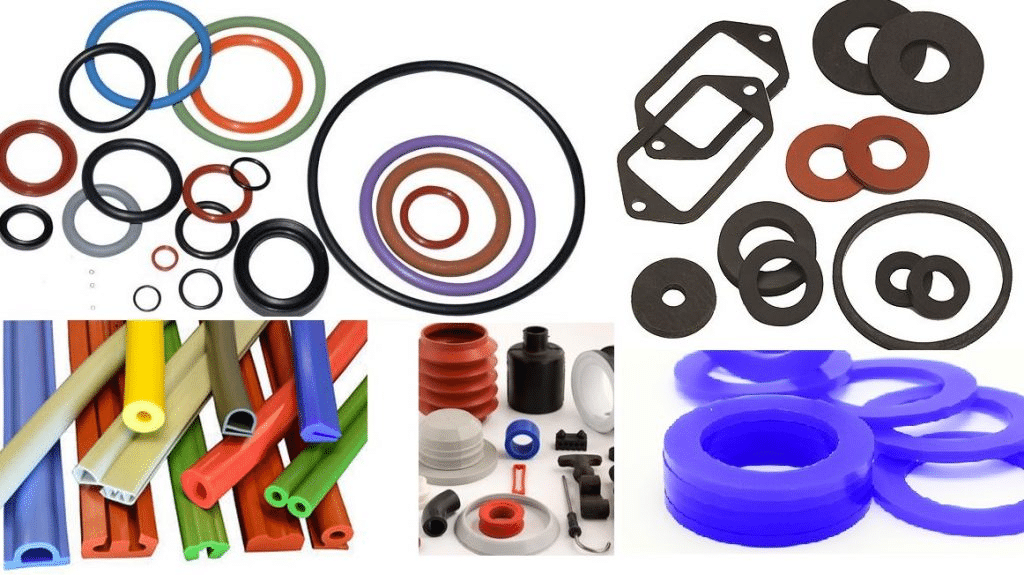

Sealing is not only a part in modern engineering, where systems work under extreme pressures, temperatures, and chemical exposures, it is the unsung hero that prevents leaching, safeguards delicate components and provides operational safety. Being the representative of Dongguan Haotian Silicone Technology Co., Ltd., a company established in 2015 and focusing on the provision of customization to multi-color and complex silicone products, I have worked on the production floor for years where I have seen how silicone has been used as the primary material in such demanding tasks. Silicone sealing usage has reinstalled the concept of reliability in automotive engines, industrial machinery, etc. with a higher performance that even such material as rubber or plastic cannot regularly reach.

Such preference is based on the fact that silicone is difficult to degrade whenever extreme conditions are experienced thus minimizing downtime and maintenance expenses. This enables us to manufacture precision seals at Haotian Silicone as we have been using our entire production process including design and opening the mould, vulcanization, printing, treating the surface and packaging, to meet the requirements of our customers worldwide such as Huawei and MINISO. Our products have received patenting on silicone multi-color integrated molding, utility model and appearance patents, and more certifications such as the ISO9001, ISO14001, SEDEX, and the BSCI. we have Disney, Universal, IPS, and other factory audits. In this paper, I will use our practical experience in my description to provide the science of silicone, its use in the automotive and industrial industry, why it is excellent compared to other material, how it is made, its quality testing, its sustainability and future developments. Be it high-performance engine engineering or a robust industrial system the reasons as to why silicone is the material of choice when it comes to sealing will demonstrate the manner in which silicone can be forward-looking in terms of efficiency and safety.

The Science Behind Silicone: What Makes It Exceptional for Sealing

The sensational sealing property of Silicone is attributed to its distinct chemical structure an elastic Si-O backbone and an organic side group that is highly stable thermally, mechanically and chemically. This inorganic structure is abrasion resistant and does not degrade under heat, oxidation and other environmental factors like stress, unlike carbon based polymers used in rubber and plastic so that the heat resistant silicone can be used over a long period of time.

Among these are: a temperature span as wide as -60degC to +230degC being the tempos of standard grades and even higher to 300degC being the tempos of specialist fluorosilicone that enables it to stay pliable when others become hard or even liquid. It is chemically resistant to Oils, fuels and ozone and it does not swell or deteriorate and its high flexibility (elongation to 700) builds seals around pressure without cracking. Electrical insulation is valuable when used around the wiring process, and its low compression set allows it to bounce away well after being deformed.

Silicone is flexible as shown by our lab tests of materials such as LSR (Liquid Silicone Rubber) to be precisely injection molded and HCR (High Consistency Rubber) to be compression molded. Not only does this chemical resistant silicone structure extend the service life; it also reduces the occurrence of failures thus making it a material that is of choice in harsh conditions.

Automotive Applications: Performance Under the Hood

Silicone has also been required in the automobile industry where engines are high-temperature, and parts in constant vibration. Automotive silicone gaskets can also be used, e.g., to close valve covers and oil pans with temperatures up to 200degC and are not subject to leaks when in contact with oil, which the old-fashioned cork or rubber classifications fail very easily.

The use of silicone hoses and connectors can be helpful in turbochargers where extreme temperature cycling can occur and will cause cracks resulting in the loss of the boost. Silicone engine seals are used to insulate battery packs and motors in electric vehicles (EVs), to provide thermal control as well as waterproofing to withstand dust and moisture. Silicone is also used in headlamp and taillight seals to avoid fogging which may result in lack of clarity during wet conditions.

As we have done on our production at Haotian Silicone where we have done custom seals to automotive clients, the aging resistance of silicone has promoted a longer life of the vehicle, hence reduced warranty claims. This renders it to be absolutely essential to sealing use with silicone in contemporary vehicles, ranging in combustion engines to EV silicone items.

Industrial Applications: Sealing Reliability in Harsh Environments

In addition to the automotive sector, silicone durability is ideal in industries, where machine performance is corrosive and/or hot. The silicone sealing used in industries encompasses flange and pipe seals used in chemical plants whereby acids and solvents resistance are important to avoid leakage which may lead to shutdowns.

Compressors and pumps are made of high-temperature gaskets made of silicone to ensure integrity under pressure, and anti-vibration seals of HVAC systems absorb shocks without breaking. Industrial-grade silicone is used in the food-processing or pharmaceutical equipment as a hygienic seal that meets FDA requirements of avoiding contamination.

The defective silicone rubber seals in Haotian Silicone projects seal industrial ovens and seals are used as examples to demonstrate the benefits of waterproof silicone seals in protecting the electrical enclosures against water ingress. It is this performance based on highly adverse conditions that goes to indicate the importance of silicone and where downtime losses can be very high.

Comparison: Silicone vs. Other Sealing Materials

In applications of high performance, silicone will always perform better as opposed to its alternatives. Here’s a breakdown:

| Property | Silicone | EPDM | NBR | Neoprene |

| Heat Resistance | Excellent (up to 230°C) | Good (up to 150°C) | Fair (up to 120°C) | Fair (up to 120°C) |

| Chemical Resistance | Excellent (oils, ozone) | Moderate | Poor (oils) | Good (weather) |

| Weather/Ozone Resistance | Excellent | Good | Poor | Good |

| Longevity | 10+ years | 5–7 years | 3–5 years | 5 years |

Silicone vs rubber gaskets illustrates that silicone is more thermal stable and elastic, which eliminates the hardening of EPDM or NBR gaskets, causing leakages. Stiff plastics such as PTFL do not have the flexibility to make dynamic seals. Although silicone is more expensive compared to its initial cost, it can be cost-effective because of its cheaper cost per lifetime due to fewer replacements. Testing at Haotian Silicone has proven the benefits of silicone seal material in its lasting and operation, particularly in situations where high stress is present.

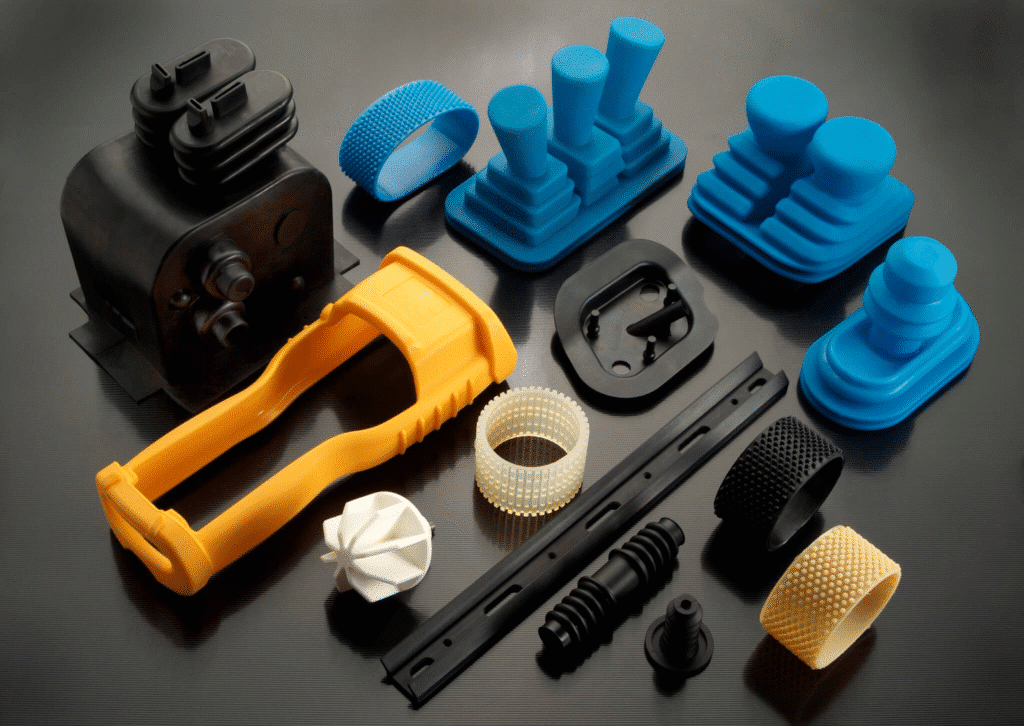

Manufacturing Process: Precision and Customization

The manufacture of silicone seals is undertaken with great care in a bid to achieve precision. In Haotian silicone, it begins with design with CAD software optimizing tolerances such as +-0.05 mm. Mold making with CNC makes precision cavities either in LSR or HCR.

Additives are included into the material to enhance performance and it is then injection/ compression molded. The silicone is enhanced by vulcanizing at 150-200degC. Adhesion is enhanced with surface finishing such as plasma treatment and flash is removed by trimming.

Our process of the custom silicone seal production with the support of ISO9001 offers an opportunity of various design- multi some colors to identify or fluorosilicone to resist fuel. This silicone molding technique produces perfect and reliable seals.

Quality Control and Performance Testing

Our Haotian Silicone is production that focuses on quality. We perform tensile and elongation tests (ASTM D412) to check on strength, compression set testing (ASTM D395) to check on resilience and also, thermal aging simulations as a check on longevity.

Resistance is checked by immersion with a chemical whereas dimensional checks are made by checking with CMM. In the case of automotive parts, we either simulate the vibration and pressure cycling. Our silicone seal tests comply with ISO9001 and BSCI making batch tests meet the specifications in every batch. This quality control on the seal which is used in industries would reduce the number of defects, and this will lead to the establishment of trust with the clients.

Sustainability and Longevity: Silicone’s Environmental Edge

With its durability, silicone helps in sustaining the environment by minimizing its replacement rate and disposal. Environmentally friendly silicone seals do not break down to microplastics in the case of some rubbers and our ISO14001 processes reduce emissions.

Silicone helps in reducing consumption of energy in EVs through leakage. Recycles like the recyclable items through grinding and reprocessing thus fits circles economies. In the case of brands, the ability to reduce environmental impact is the result of this prolonged industrial gaskets aspect and makes silicone a green option.

Future Trends: Advanced Materials and Smart Sealing Solutions

The future entails the use of fluorosilicone seals to biofuels, along with the use of tear strength hybrid blends. There is the emergence of smart sealing with sensors which predictive maintenance and this is combined with the IoT which provides real time monitoring.

Even better silicone material such as self-healing material will further increase life. We are investing in these at Haotian Silicone, and this will place the company at the next era of silicone sealing.

Conclusion: Why Silicone Remains the Preferred Material

Silicone has a combination of acceptance, stability, flexibility, and safety, thus making it a material of choice for automotive and industrial sealing, which outperforms other materials under harsh conditions. We are Haotian Silicone, which promises high-quality engineering accuracy and innovation will maintain a stable solution to a reliable silicone sealing manufacturer. For global clients seeking custom automotive silicone seals or industrial-grade options, silicone is the future-proof choice—contact us at bella@htsilicone.com to explore how we can support your needs.# Silicone in Automotive and Industrial Sealing Applications: Why It’s the Preferred Material