Introduction: The Versatility of Silicone in Modern Life

Silicone has gained its reputation as being one of the most versatile of the 21 st century, and it combines unsurpassed flexibility, strength, resistance to heat, safety, in a combination that few other materials can match. Being the representative of Dongguan Haotian Silicone Technology Co., Ltd. which is the one established in 2015 and engaged in creating the tailor-made solutions of silicone that may be used in multi-color and in complex parts, I have also witnessed how this material alters the same items and even the industrial components. Its silicon-oxygen backbone has a high potential of stability in that the temperature range is between -60degC and +230degC with resistance to chemicals and non-toxic characteristics that make custom silicone products a snack in the various industries.

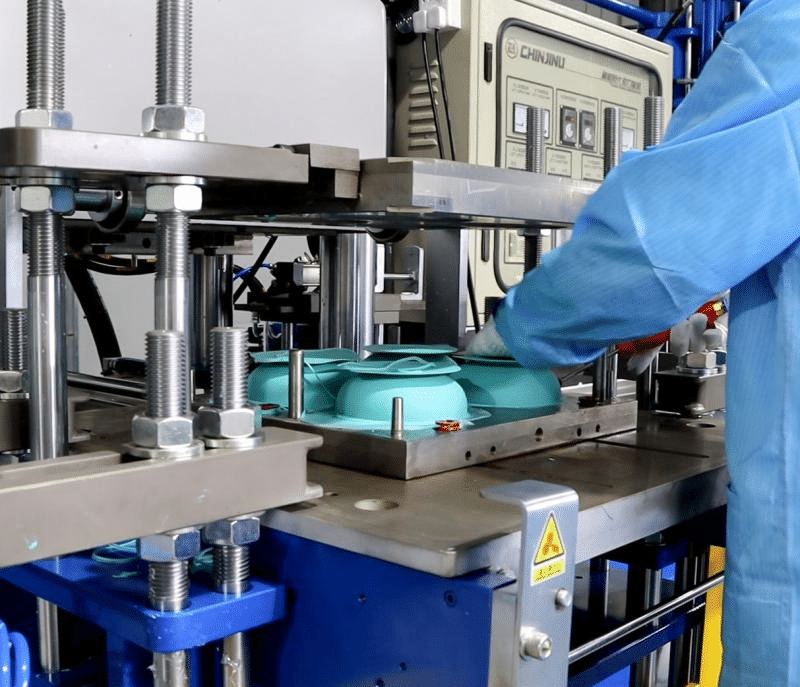

Silicone usage has grown in consumer electronics to aerospace engineering and is expected to further continue its development due to its potential relative environmental friendliness and ability to be customized. It makes life more convenient, safe, in the industry, more reliable and efficient. Due to high-tech production methods, such as our multi-color patented integrated molding, which provides high accuracy in colored designs with no loss in performance. In this guide, I will discuss the best 10 uses of custom silicone products using our experience with such global brands as Disney, Universal studios, Huawei, and MINISO. We shall begin with general knowledge and focus on particular applications by explaining why silicone will continue to be the material of choice even in 2026 and beyond.

Section 1: Kitchenware and Baking Tools

Silicone is now the material of choice in making innovative tools, particularly in the kitchen where heat, moisture, and frequent use put the material to the test. Such silicone baking mats as custom silicone mats, offer non-stick baking surfaces of parchment paper capacity, withstanding high oven temperatures (up to 230degC) without distortion or exhalation of toxins. Clients usually demand customized sizes or brand, and we use the versatility of silicone to be able to roll and carry it around.

Silicone is used in the manufacture of kitchenware such as spatulas, molds and food storage lids; they are heat and dishwasher safe thus cleaning them is not a problem at all. Food-grade silicone, unlike plastic, will not melt or leak chemicals and will not transfer its flavor or be contaminated, which meets the FDA and LFGB standards. This is why it is perfect in bakery lovers as well as professional cooks in which the silicone baking mats could be customized to a certain size of tray or design, which both improves effectiveness and brand in both domestic cooking and professional chef operations.

Section 2: Baby and Infant Products

When considering products of the most vulnerable clientele, safety is a key factor, and non-toxicity, non-BPA is one of the most prominent characteristics of silicone that can be used when choosing an item to provide to a baby. Silicone baby products such as bottles, nipples, and bowls are soft and durable and will not be bitten or dropped, are easy to sterilize using boiling water or the microwave.

We have created bespoke designs on brands targeting eco-friendly parents, including foldable silicone bowls which which save on space and will not crack even after undergoing heavy wash ups. The hypoallergenicity properties of the material do not cause allergy and the material has the flexibility of being similar to the skin thus allowing it to be comfortable when feeding. These baby silicone bowls can be used in real life as they minimize plastic waste, as a more sustainable choice and infants friendly, tough enough to withstand everyday use.

Section 3: Personal Care and Beauty Tools

The non-porous coating and antimicrobial properties of silicone have transformed the personal care industry, which is important in hygiene and soothingness. Individually crafted silicone beauty items including makeup brush scrubbers, scrubbers, and exfoliating pads are a gentle, efficient way of cleaning that does not irritate the skin.

In the case of the brands, customization can be made of the ergonomic form or branded color that will improve user experience. The fact that silicone cannot be a source of bacteria accumulation imparts the ability to keep the tools cleaner, unlike sponge or nail brush for a longer period, and they can be washed completely. In everyday life, a brush silicone holder makes counters clean, and its disposition can last long since it is durable and lasts much longer than the plastic ones that contain dirt or fracture so easily.

Section 4: Electronics and Consumer Devices

Silicone offers protective and versatile solutions to a fast-paced consumer electronics that experiences fall, heat, and dust. The silicone phone cases are shock absorbing and gripping and custom designs including logos or patterns in silicones through our multi-color molding.

In addition to cases, silicone electronic accessories, such as cable jackets and keyboards covers, are wear insulated to remain flexible in cold or hot environments. In the case of wearables, electronics could be made using silicone components that are customized to be comfortable, waterproof, like in the case of smartwatch straps, which can breath and still contain internals. This application will bring up the need of silicone to increase the life of the devices and this will be an indispensable element to tech savvy consumers.

Section 5: Automotive and Mechanical Components

Moving to industry, the strength of silicone finds its way to the automotive industry, where temperature and vibrations extreme conditions require materials that are very tough. Silicone seals and gaskets are able to withstand 200 deg c and above without drying up as compared to rubber which hardens due to age.

Automobile siliconizing fittings are engineered to be vibration damping and oil resistant, with special parts customized to fit particular automobile models. Industrial silicone seals used in mechanical systems are taken so as to maintain airtight work between pumps or valves which minimizes downtime. That is evidenced by our experience with long lasting parts in OEMs where failure is not an option and silicone is highly reliable.

Section 6: Medical and Healthcare Equipment

Biocompatibility of silicone has enabled it to be a health sector staple wherein purity and performance save lives. Tubing, seals, and prosthetics are made of medical-grade silicone, and since placed in sterile, can be sterilized over and over again without losing its properties or shedding particles.

Patient-specific solutions such as respiratory masks with soft sides to make them comfortable are also designed by hand. It is chemically inert meaning that it does not react with anything and thus biocompatible silicone can be the best choice in the case of implants or wound cover. Silicone healthcare applications also have drug delivery devices, in which the precision molding would guarantee effective dosing in the emerging applications.

Section 7: Industrial and Engineering Uses

Outside the automotive industry, silicone has served the industrial requirements of heavy-duty thermal and electrical insulation. Silicone products such as sheets and pads are used in industries to absorb shocks in machineries and also the high temperature areas use heat-resistant silicone to shield wiring.

Antivibration mounts that are designed to order are the ones that minimize noise in factories and silicone application of insulations in cable shields abraded cables. Its durability reduces maintenance in engineering and therefore it is cost effective in tough environments such as power plants or construction.

Section 8: Promotional and Branding Products

In the case of marketing, the customizability of silicone makes ordinary products brand ambassadors. The wristbands are one form of giveaway that are durable and can withstand sweat as well as wear, though they may be embossed with logos, which are custom silicone wristbands.

Promotional item promotions such as keychains or coasters can be in a variety of colors through multi-color molding, which increases visibility. Engraved siliconed gifts create loyalty, since they are useful enough to be used again, which delivers brand messages indirectly.

Section 9: Home and Lifestyle Accessories

Silicone helps in organising and creating style in the daily life of homes. Anti-slip mats are made of silicone home items such as anti-slip flooring which makes floors non-slip and makes the countertop or desk quite easy to wash.

There are cable holders and organizers that make spaces clean, and lifestyle silicone products can be modified to an individual color or a pattern. They are modern and minimalistic due to their waterproofness and their resilience.

Section 10: Emerging Fields — Sustainable and Smart Applications

In the future, the sustainability of siliconic products is going to be made possible by environmentally-friendly siliconics, such as reusable straws and collapsible bottles that reduce plastic waste. Wearables are flexible, a combination of sensors in smart silicone, used to track health.

Durability and environmental responsibility: Sustainable silicone production such as recyclable composite put it at the forefront of the green trends in 2026.

Section 11: Why Brands Choose Custom Silicone Solutions

Custom silicone production is chosen due to its longevity, reusability, and ability to be branded, such as colors, logos, shapes, etc, with processes such as our patented molding. FDA, LFGB, and REACH ensure safety, whereas production that considers the environment is a benefit to appeal to a modern buyer. Being an OEM supplier of silicone, Haotian Silicone regards silicone as the future-proof material in silicone applications both in industry and in daily innovations.