Introduction: The Shift from Plastic to Silicone

Silicone has conclusively performed better than plastic in various applications, in dynamic environment in modern manufacturing where environment regulations have become more stringent and consumer requirements of durable and safe products have increased. I am the founder and the chief engineer of Dongguan Haotian Silicone Technology Co., Ltd. that was founded in 2015 and focuses on the production of customized multi-color and complex silicone products, and I have personally observed this change. The world has been very concerned about plastic pollution, which has risen to produce more than 400 million tons of plastic waste a year with most of it finding its way in to the oceans, and the performance constraints such as brittle nature, loss of chemical substances has led to the desire to use silicone as better way of doing things.

The remarkable resilience coupled with the environmentally friendly nature of silicone makes it now the choice of material in all types of medical devices and even electronics consumed by individuals. It is not merely a trend, but a requirement in 2026, when the 2.1 reusable, durable materials are encouraged by laws such as the EU’s Single-Use Plastics Directive. I will use our experience in the OEM/ODM production, where we have a patented multi-color integrated molding process, to discuss why silicone is superior to plastic, in this article. We are going to discuss performance advantages, environmental advantages, safety advantages and practical implications, and you would have an idea of how this material is transforming the present-day manufacturing materials to make the future more sustainable.

Section 1: Understanding the Materials

In order to understand why silicone is superior to plastic, there is need to understand the basic distinction between the two. Silicon is an inorganic elastometer that is made of silica (sand), oxygen, carbon, and hydrogen to create a stable silicon-oxygen backbone to provide it with special properties. Our silicone processing is done by means of vulcanization in our factory which produces elastic but sturdly reinforced products such as custom silicone mats or phone cases. This silicone chemical framework is not prone to breakdown and this renders it non-toxic by nature and a general purpose chemical.

Plastic, however, is usually a petroleum product which is a polymer, perhaps polyethylene or PVC, made out of long strands of carbon which may be rigid or flexible but commonly depend on additives to stabilize them. The comparison of the plastic polymers shows the advantage of silicone: when plastics are inexpensive because of fossil fuel as a source, they fail and release microplastics or volatile substances. Silicone silicone is a synthetic material that is made of silica, which is available in large amounts hence a cleaner profile without the environmental baggage of being oil dependent. We have had experience with our production line passing audits with such brands as Disney and Universal, and having the purity of silicone allows us to certify with other such agencies as FDA and LFGB, something plastics can barely do because of potential contaminants.

Section 2: Performance Comparison — Silicone vs Plastic

In head to head comparisons of silicone against plastic in evaluations that are conducted based on our stringent quality standards under ISO9001, silicone has always performed better in all the major metrics. Take heat resistance: silicone has a temperature range of -60degC to +230degC, without loss of integrity, so can be used in the oven as a type of kitchenware or anywhere in the car as a seal. Some plastics such as polypropylene melt or deform at temperatures of 100-160degC, which restrict their use in hot temperatures.

Silicone also has the benefits of durability and flexibility. Silicone is elastic with a maximum of 700 percent elongation and can be stretched to its original shape after repeated repeated stretching, whereas plastics break down over time and crack under the influence of the UV rays or mechanical forces. This silicone durability ensures that such products as custom rubber gaskets can last several years and thus help to minimize failures in the industrial context.

Another victory is chemical resistance: Silicone will not mix with oils, solvents, ozone, and UV radiation, and thus will not yellow or break up, as plastics do. An example is the idea of silicone vs plastic strength where, in the outdoor environment, the silicone holds 90% of its strength even after 5 years of exposure opposed to plastics where they lose 50 of the same.

The deal is closed by safety, when silicone is a non-toxic, odorless and BPA-free substance, which received food-grade certifications, and plastics may release endocrine disruptors. The longevity is what holds it all together: the long life of the silicone, which can be between 10-20 years, which is comparatively more than 2-5 in the case of plastic, reduces the replacement requirement, and promotes efficiency in the current production.

Section 3: Environmental and Sustainability Impact

The environmental cost of plastic which makes up 8 million tons of ocean waste per year has propelled silicone that is environmentally friendly as a material to replace plastic. The low-waste production and scrap recycling into new materials are a part of our ISO14001-certified procedures at Haotian Silicone, whereas the single-use cycle of plastic contributes to the spread of microplastic pollution.

The reusability of silicone is very bright: Such products as silicone bottles designed upon order can be reused thousands of times without becoming useless. Its reduced carbon footprint – less energy is used in the production of eco-friendly silicone – is in line with the green factory production targets in 2026, where it is ensured that emissions are reduced. Whereas plastics are produced out of the limited oil, silencium consumes large amounts of silica, which encourages sustainable materials production. The philosophy of our Four Hearts Progressive, Tolerant, Awe and Grateful makes us find a way to innovate to low-impact vulcanization to show how silicone can help us in a greener future.

Section 4: Applications Where Silicone Excels

The versatility of silicone renders it to be invaluable in the areas where plastic has failed. Silicone is also used in non-toxicographic medical and health industries, as a substitution of PVC tubing with sterilizable, flexible options, which do not leech out during repeated autoclaving. The silicone uses in prosthetics and seals are evidenced in our partnership with such brands as P&G.

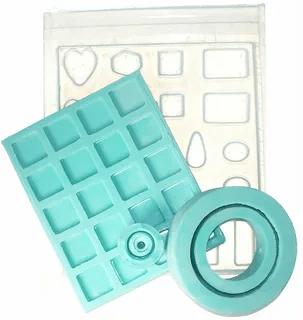

In the case of food and beverage, food grade silicone vs plastic, silicone would be preferred due to its characteristics of mats and lids, FDA certified and heat stable, unlike melting plastics. Silicone in electronics offers better insulation in electronics that plastic housing cannot endure.

It has a positive impact on consumer goods as well: Silicone wristbands and phone cases have branding flexibility through our multi-color injection molding and wear longer than plastic equivalents every day. These illustrations underscore the flexibility of silicone in the contemporary environment.

Section 5: Cost-Benefit and Production Efficiency

The raw material of silicone is 20-50 percent more expensive than plastic, but its long-term performance puts the tables on reverse. Our LSR manufacturing, which is liquid silicone rubber injection, minimizes the wastage in silicone production due to the accuracy in dosing; and the cycle time is under 60 seconds compared to the problematic molding of plastic.

Comparison of silicone and plastic costs demonstrates that the lifespan of silicone is 3-5 times higher and, therefore, fewer replacements are necessary, which lowers the total costs. Scalable production is guaranteed by in-house tooling and BSCI-compliant, which means that silicone can be used in high-volume OEMs. To the clients such as Huawei, this is translated to premium value without premium waste.

Section 6: Consumer and Industry Perception in 2026

Consumers do value safety and sustainability more by 2026, with silicone appearing to be the new luxury, with tendencies such as eco-wearables and reusable kitchenwares emerging. Electronics and baby products, which are major brands, prefer silicone because it is hypoallergenic to increase loyalty.

There will be smart integrations such as conductive silicone to use in sensors, which will surpass rigid plastics in the trend of silicone products in the year 2026. The innovation of silicone manufacturing, which is utility patented, has put us in a position to achieve this demand because the industries have realized the involvement of silicone in long-lasting responsible designing.

Section 7: Expert Conclusion — The Future Is Silicone

In a wrap up, it is important to note that plastic made the past; whereas silicone is making the future-it is unmatched in terms of durability, safety, and sustainability. With Haotian Silicone still investing in research and development, manufacturers adopting silicone will be the best quality and environmentally friendly. It is understandable why silicone is beneficial in the industry: it is time to switch to a more resistant tomorrow.