Introduction: Silicone and the Modern Electronics Revolution

As smart devices continue to be part of everyday living (including smartphones and wearables, as well as internet of things devices) interest in material protecting, insulating, and supporting these innovations has increased. Founded in 2015, Dongguan Haotian Silicone Technology Co., Ltd. is a company that deals with customized multi-color and complex silicone solutions and we have witnessed this change in action, having been collaborating with the likes of Huawei and MINISO. It is worth noting that silicone is the material of the first standing in the creation of electronic accessories because of the outstanding characteristics which include flexibility, resistance to heat, electrical resistance, and non-toxicity. Contrary to hard plastics or hard rubbers, silicone has impact absorption qualities, environmental resistance and complex designs that can be easily incorporated into the device of the present day.

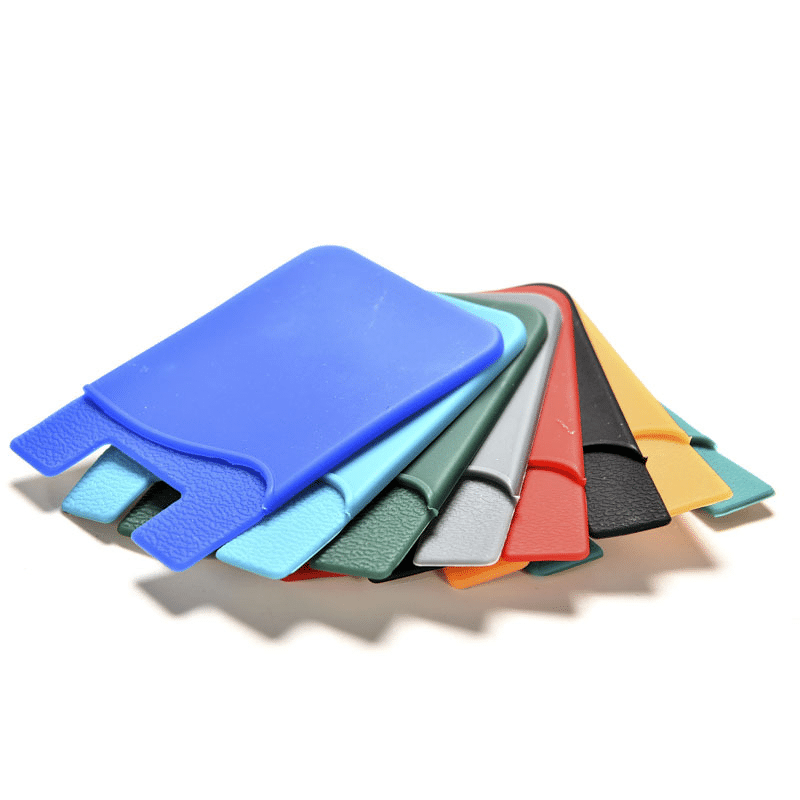

The latter change can be explained by consumer demands of long-lasting eco-friendly protection and industry demands of high-quality components. The personalized silicone accessories not only protect the devices but they provide a colorful branding opportunity by use of colorful colors and logos. This guide will examine the uses of silicone in electronics, including its main benefits, defining the important uses of silicone, discussing its manufacturing, customization, quality assurance and its future. Regardless of whether you are creating a project that is a silicone phone case manufacturer or whether you are looking to study silicone as the preferred material in electronics, these factors will bring to light the reasons why this material cannot be excluded in the technological world in 2026.

Section 1: Why Silicone Is Ideal for Electronics

The attraction of silicone in electronics is due to its material profile which is the result of years of experience in making Haotian Silicone productions. It has good thermal insulation and can withstand temperatures between -60degC and 230degC which means that it does not store heat in devices such as chargers or batteries; much better than plastics which distort and melt at a much lower temperature. Another strength is electrical insulation: being non-conductive (dielectric strength up to 500 V/mil) Silicone can resist shorts, thus being hygienic, unlike conductive rubbers.

Impact absorption cushion: flexibility and impact cushion which also drops with a maximum elongation rate of 700 and absorbs shocks cracking hard materials. Its ability to withstand UV, ozone and oxidation makes it last longer in the outdoors and its waterproof (IP67+ ratings are possible) cannot be ruined by moisture. Silicone does not leech chemicals in comparison to plastic, hence it complies with the requirements of RoHS and REACH on safety. Our OEM applications have found the versatility of this heat-resistant silicone a useful tool in having a functional and aesthetic design, making it the non-conductive silicone material of choice in the current electronics industry.

Section 2: Core Applications in Electronic Accessories

a. Phone and Tablet Cases

Silicone phone cases are a commodity of consumer electronics with they being very durable protection but non-bulky in package. At Haotian Silicone, we had made our own silicone case manufacturer lines of the brands that require shock proof design and is able to absorb the shock when it falls up to 2 meters. Soft feel of the material improves grip and reduces slips and the material is highly flexible which enables the cutouts of ports and cameras to be made accurately.

Silicone also has the benefits of dust resistance and being easily cleaned, unlike fabric cases. To be customized, we implement multi-color molding of branded patterns, and we create protection silicone cover options, which are in tandem with lifestyle techs. Such applications increase the life of the device in day to day life, which makes silicone worthwhile in high wear applications.

b. Cable Sleeves and Wire Protection

Cables are in a form of constant bending and exposure, and silicone cable sleeves prove to offer vital protection. We are producing heat resistant cover design cable covers to prevent fraying effects on USB or HDMI cable and can withstand a temperature of 200degC due to heat generated by the device.

The elastic nature of silicone enables the cables to bend without breaking, whilst the insulation prevents the electrical risks. In the case of brands, custom lengths and colors are an addition to the aesthetic value. Applied practically, such wire protection silicone solutions make a game setups or office setting where the ground rule is the longevity of its cables to be more resistant to entangling.

c. Keypads and Buttons

Keypads and buttons used on remotes, keyboards, or control panels Tactile feedbacks can be assigned to silicone to enable good aspects in handling matching remotes. We design tailor made silicone buttons whose shape is hard (30-60 Shore A) to have responsive clicks so that they wear out in billions of actuation.

Its conductless qualities eliminate shorts, as well as ensure cleanliness of mechanisms by their dust resistance. In the case of electronic control silicone products we incorporate multi-color, to do simple design-equipment, such as, color-coded functions in an industrial remote. This ultra fine-tuning is molding that provides confidence in use in consumer gadgets.

d. Seals, Gaskets, and Connectors

Silicone electronic seals are important to IP ratings in waterproof electronics such as earbuds or smartwatches. Our custom silicone gasket manufacturing is concentrated in regards to compression set resistance by seals maintaining under pressure.

These silicone gallons that are waterproof can withstand vibrations and hard chemicals, and they are appropriate in the connectors that cannot withstand harsh environments. In the case of brands, close fits (+-0.05 mm) are perfect fits that do not leak. Silicone exhibits its sealing ability in use at this front as well since in applications such as drone housings, the material expands as weight inclusion increases and its reaction is elastic in such situations.

Section 3: The Manufacturing Process of Silicone Electronic Accessories

Designing of silicone covers of electronics is a tedious process, requiring design and computer aided design to conform to the specifications of the device-cutouts. Mold fabrication Mold fabrication involves CNC and EDM, which is done to tooling from the complex shapes.

LSR or HCR silicone is then chosen in preparation of materials, where matching in color is also mandated to be used as branding. Molding- through compression or injection forms parts then post-processing such as trimming and grip-coating. Our silicone molding technique is patented as being multi-color and produces finishes smooth, so our custom silicone manufacturing method is accurate and long lasting to meet the requirements of electronics.

Section 4: Advantages of Using Custom Silicone in Electronics

Silicone has benefits in electronics such as excellent shock absorbency, it impacts cushions on glass or plastic. Its electrical insulation allows it to be short proof and its heat resistance enables it to address device heating without losing heat.

The eco-friendliness is important – silicone can be recycled, and it is not toxic, which has lesser effects on the environment as compared to PVC. It is flexible in terms of design enabling color and texture control, which improve user experience. To the brands, silicone heat resistance as well as shockproof silicone accessories provide the brand with longevity, reducing warranty claims and increasing customer satisfaction.

Section 5: Brand Customization and OEM/ODM Services

Silicone accessories are customized, and include such options as embossing logos, or matching Pantone colors, through our multi-color process. Silicone branding also has the option of laser engraving to permanent use, which is applicable to high-end phone cases.

Being a partner of custom silicone end-to-end solution OEM manufacturer, Haotian Silicone offers tech brand-specific end-to-end solutions, including prototyping and packaging. We have China capabilities of our silicone accessory manufacturer which is audited by Universal and IPS and has the ability to produce on an extensive scale which is palatable to your vision.

Section 6: Quality Control and Compliance

Reliability: We check tensile strength, hardness, and insulation according to the ISO9001. Electrical tests confirm non-conductivity and adherence to RoHS, REACH, FDA and LFGB are tests that ensure safety.

Our silicone product tests involve drop tests and heat cycling, which is consistent. Such an approach of manufacturing in line with ISO certification of silicone gives confidence in the global delivery.

Section 7: Future Trends — Silicone in Smart Devices and Sustainability

With the development of smart devices, wearable devices will incorporate silicone that provides biocompatible and flexible surfaces. Other trends in silicone manufacturing involve sustainable manufacturing, which involves the use of bio-based formulations, and carbon footprints reduction.

By 2026, environmentally friendly possibilities such as cable recyclable composites should be expected. We are in a position to be a trusted OEM/ODM company at Haotian Silicone proposing trusted custom silicone electronic accessories to spearhead the new era of technological innovations.