Introduction: The Global Shift Toward Sustainable Manufacturing

Sustainability has become the legend behind the manufacturing industry in the age when climate change, resource depletion, and ethical requirements of consumers are molding the world industry. Firms are being compelled to lower their carbon footprints, waste generation and use of materials that can facilitate a healthy environment of environmental health in the long term-trends that will grow even further by 2026. I have experienced this change as the representative of Dongguan Haotian Silicone Technology Co., Ltd. a manufacturer based in 2015 that focused on customized solutions of multi-color and complex silicone products. Our entire production process, including design and mold opening, vulcanization, printing, surface treatment, and packaging has also been made more environmentally friendly and we have certification such as ISO9001, ISO14001, SEDEX, BSCI, and are also subject to factory audit of Disney, Universal, IPS, and others.

Silicone is one of the prime examples of sustainable materials that would also serve as an alternative to petroleum-based plastics and rubbers that are the source of the pollution as well as non-biodegradable waste. Its performance to deliver high performance and at the same time blend with solutions to green manufacturing is making it more preferred as far as products as far as kitchenware to industrial components are concerned. The paper will seek to address the reasons why silicone is a green product, its nature and properties, waste-savings, eco-cyclic, eco-energy foodstuff, safety, alternative materials, eco-design, responsible manufacturing, and perspectives of innovation. The knowledge of silicone sustainability will help brands and manufacturers make informed choices that will not be harmful to business and planet.

What Makes Silicone an Environmentally Responsible Material

The sustainable character of silicone starts with its basic structure which is a polymer that is made of silica (common in sand), oxygen, carbon and hydrogen, implying that it is less dependent on non-renewable fossil fuels as most of the plastics. It is a stable, non-toxic, and inert eco-friendly material made of silicone with no volatile organic compounds (VOCs) or microplastics release when used or degraded, as is naturally stable, unlike petroleum-based materials which pollute waterways and soil.

In our manufacturing at Haotian Silicone we specialize in platinum-cured formulations which do not produce byproducts of peroxides which means cleaner production. Silicone is resistant to UV, ozone and temperature (-60 degenerate C to +230 degenerate C) so no chemical decay occurs prematurely, this is translating to longer product life and less replacement. This is a non-toxic silicone, so bacteria and mould cannot survive in and therefore, needs no extra chemical additions to be used in food-contact and medical requirements. On balance, its sustainable production of silicone uses raw materials, which are plentiful and processes that have low environmental effects, which makes it a responsible option to industries that need to limit its impact.

Long Lifespan Means Less Waste

The outstanding usefulness of silicone is its high level of durability and this directly shows to reduced wastes in the long run. Silicone goods have a lifespan, but they can last years of service without taking on any damage- e.g. silicone baking mats last more than 2,000 uses, which is more work than disposable parchment paper. Silicone seals and gaskets are used in industrial environments to ensure and ensure the performance of 10-20 years, rather than the 5-7 years of rubber, reducing the rate of replacement and usage resources.

This longevity is attributed to the fact that silicone does not suffer thermal cycling, chemical, and mechanical stresses through which cracks and erosion are caused resulting in premature disposal. To the brands, it implies a reduction in the quantity of products in landfills and reduction in long-term expenditure. In the case of our experience at Haotian Silicone, consumers such as P&G enjoy long-lasting silicone feeding sets which can be applied on numerous children, which is the adoption of waste reduction materials in practice. Silicone makes it possible to use silicone to last longer, which would aid in helping the 400 million tons of plastic waste that is produced each year on a global scale.

Reusable and Recyclable: The Circular Advantage

Silicone can easily integrate into the round economy model whereby one can reuse their materials, remanufacture them or even recycle them as opposed to disposing them. Recyclable silicone, unlike many other plastics which are used to make products of a lower grade, may be recycles as granules into new products such as industrial mats or fillers, preserving the majority of its original properties. European and U.S. programmes are increasing silicone recycling, which reinvents waste into reusable materials.

We also plan the reusability of products at Haotian Silicone, our custom silicone bottles and mats come in dishwasher-safe and durable facades, promoting their repeated use instead of single-use products. With a circular system, it is possible to gather end-of-life silicone and reprocess it, minimizing the requirements of the virgin material. This reuse/silicone strategy is in line with the international strategies, such as the Circular Economy Action Plan of the EU, in which the long-term durability of the product reduces the environmental impact. To manufacturers, it implies reduced costs on sourcing raw materials and greener supply chain and silicone is a trailblazer in circular economy materials.

Energy-Efficient Manufacturing Processes

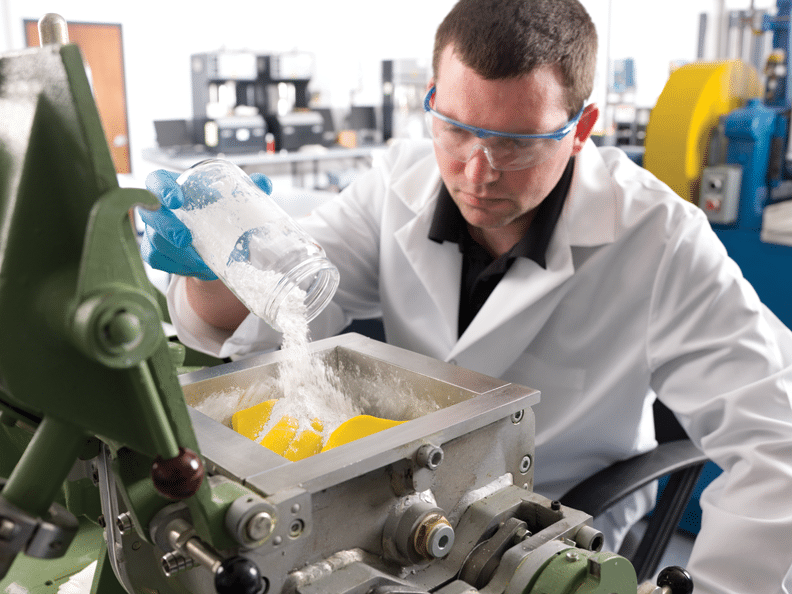

Today manufacture is more energy-efficient and plants such as ours in Haotian silicone factories are using optimised manufacturing systems to use less energy. Our vulcanization processes involve high-efficiency ovens which significantly reduce thermal waste, which in turn reduces energy consumption by 20-30 percent as compared to the old processes. Feeding and injection molding are also automated to streamline the operations and decrease the manual work and waste.

The colouring processes, urethane solvent emissions reduction, and our ISO14001-conformant environmental management is water based, which also guarantees low carbon production by heating waste heat reuse and integrating renewable energy. As an example, our multi-color molding patent can be done simultaneously, which is time and power-saving. This silicone, which is energy efficient, lowers our foot print, and also makes our sustainable products more affordable to the clients, and this demonstrates that sustainability in operations do not necessarily mean low performance.

Safety and Compliance: Protecting People and the Planet

Greener manufacture can be applied to the human and ecological safety and in this case, the silicone is very non-toxic. It is BPA, phthalate, and heavy metal-free, which is why it is safe when used as direct contact, and it is certified by FDA and LFGB to use in food. Silicone does not migrate chemicals even at high heat which plastics do and thus in our testing, silicone is non-toxic to a real degree, which plastics normally is.

RoHS and REACH regulate the use of hazardous material and BSCI and SEDEX regulate good working labor ethics. These norms apply to the protection of workers and the environment as at Haotian Silicone, the scraps are recycled using zero-waste programs. The silicone solution is RoHS compliant and thus is a method to protect the environment as it does not pollute it and thus it is a responsible solution to brands that have chosen safe and green production.

Silicone vs. Plastic: The Sustainability Comparison

Silicone is more sustainable than plastic as seen in the comparison below:

| Property | Silicone | Plastic |

| Source | Silica-based (renewable sand) | Petroleum-based (fossil fuels) |

| Durability | 10–20 years | 1–3 years average |

| Temperature Resistance | -60°C to +230°C | Deforms easily above 100°C |

| Reusability | High (reusable, recyclable) | Limited (often single-use) |

| Environmental Safety | Non-toxic, inert | Can release microplastics |

Silicone vs plastic sustainability demonstrates the lower impact of silicone on life cycles, because its life cycle lessens the production requirements, and the nature of inert silicone cannot pollute. Plastics are a cause of microplastic disasters, but silicone cannot do the same. The scope of this comparison of non-toxic materials gives silicone a winning hand against eco-friendly silicone products because it is a greener option which does not affect the performance of a brand.

Eco-Design: Customizing for Sustainability

Eco-design using silicone entails the design of products which have least cradle-to-grave effects. To reduce single-use plastics at Haotian Silicone, we cooperate on custom sustainable packages, such as reusable silicone bags. The use of convertible kitchen tools as multi-purpose objects is an extension of utility, which reduces consumption.

The inclusion of recyclable molds as well as the use of natural pigments is compatible with green silicone production. In the case of our clients such as B.Duck, we were developing eco-design products, durable and attractive, which supported the corporate sustainability in the market and increased the market interest.

Reducing Environmental Impact Through Responsible Production

Haotian Silicone responsible production also covers waste management such as the recycling of scrap into new materials and curing with low emissions to reduce VOCs. The sustainable silicone plant also operates with energy audits to optimize it, with 15 percent savings in the use of energy.

The production of green energy using solar panels and effective logistics dramatically reduces the emission of transport. The practices will make sure that our low emission production makes the planet cleaner, a standard in the industry.

Future Outlook: Innovation in Sustainable Silicone for 2026 and Beyond

The future of silicone is the inventiveness of silicone blends, which are biodegradable and which contain bio-based additives to be compostable and without loss of strength. Recycling will be moved forward to closed-loop systems and self-healing properties of smart materials will prolong life.

These are the same R&D that our Haotian silicone is oriented towards, making us the future of silicone material. Sustainable manufacturing will be propelled as more and more people are seeking eco innovation in silicone.

Conclusion: Silicone as the Cornerstone of Sustainable Manufacturing

The strength and safety, as well as recyclability of silicone, can be deemed as the key to sustainable manufacturing which will provide a way to manufacture more environmentally regarding greener production. At Haotian Silicone, our commitment to eco-friendly silicone products and responsible practices positions us as a leader in this space. For brands seeking sustainable solutions, silicone is the future—contact us to explore how we can partner for a better tomorrow.